The Engineering

Terrawarden Drone

I wanted a big drone and got more than I bargained for: Terrawarden. A 1-meter quadrotor that can spot soda cans, grab them with a tiny robot arm, and (mostly) land the right way up.

- SolidWorks

- PX4 & ROS2

- Integration Hell

- Computer Vision

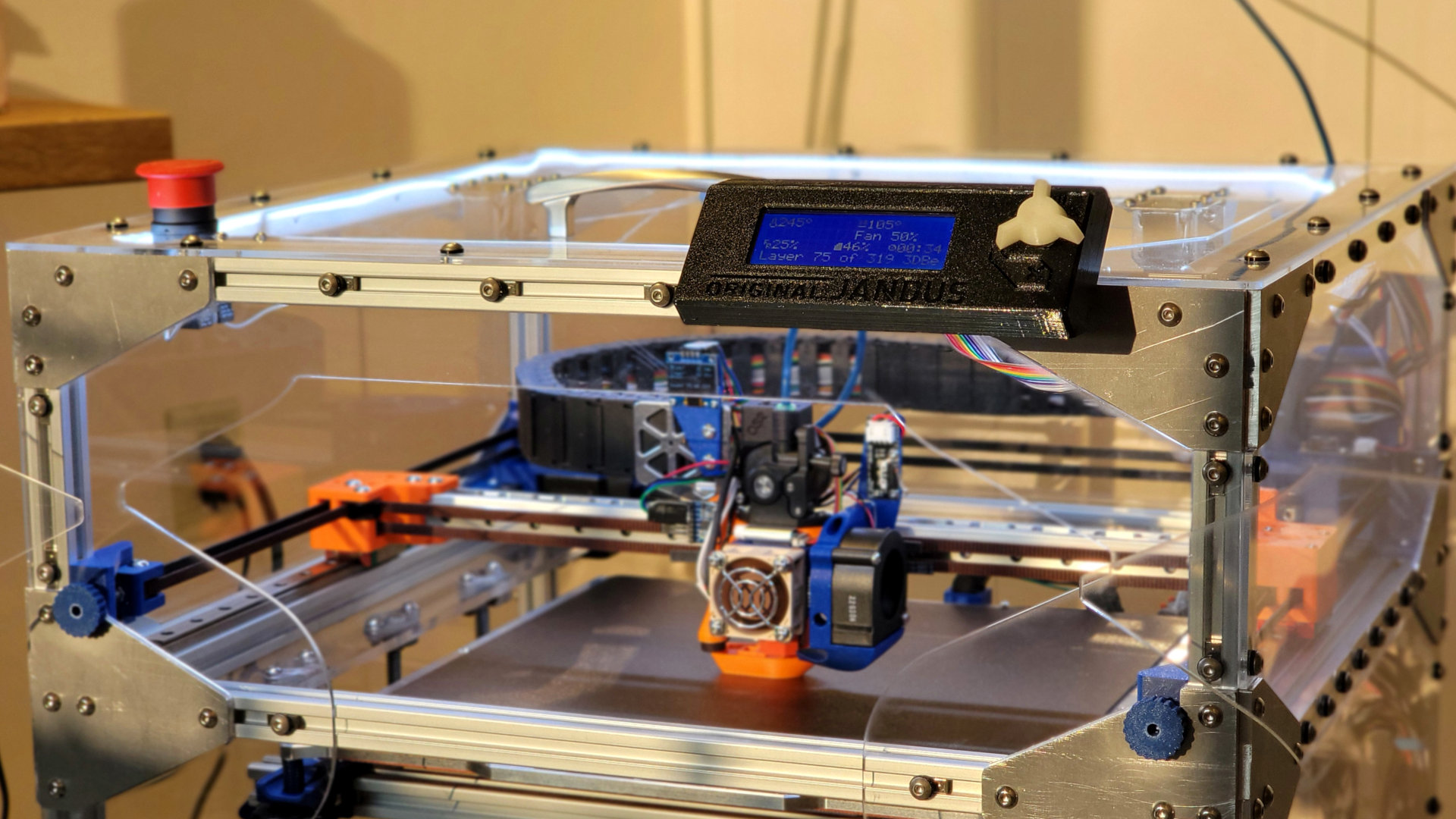

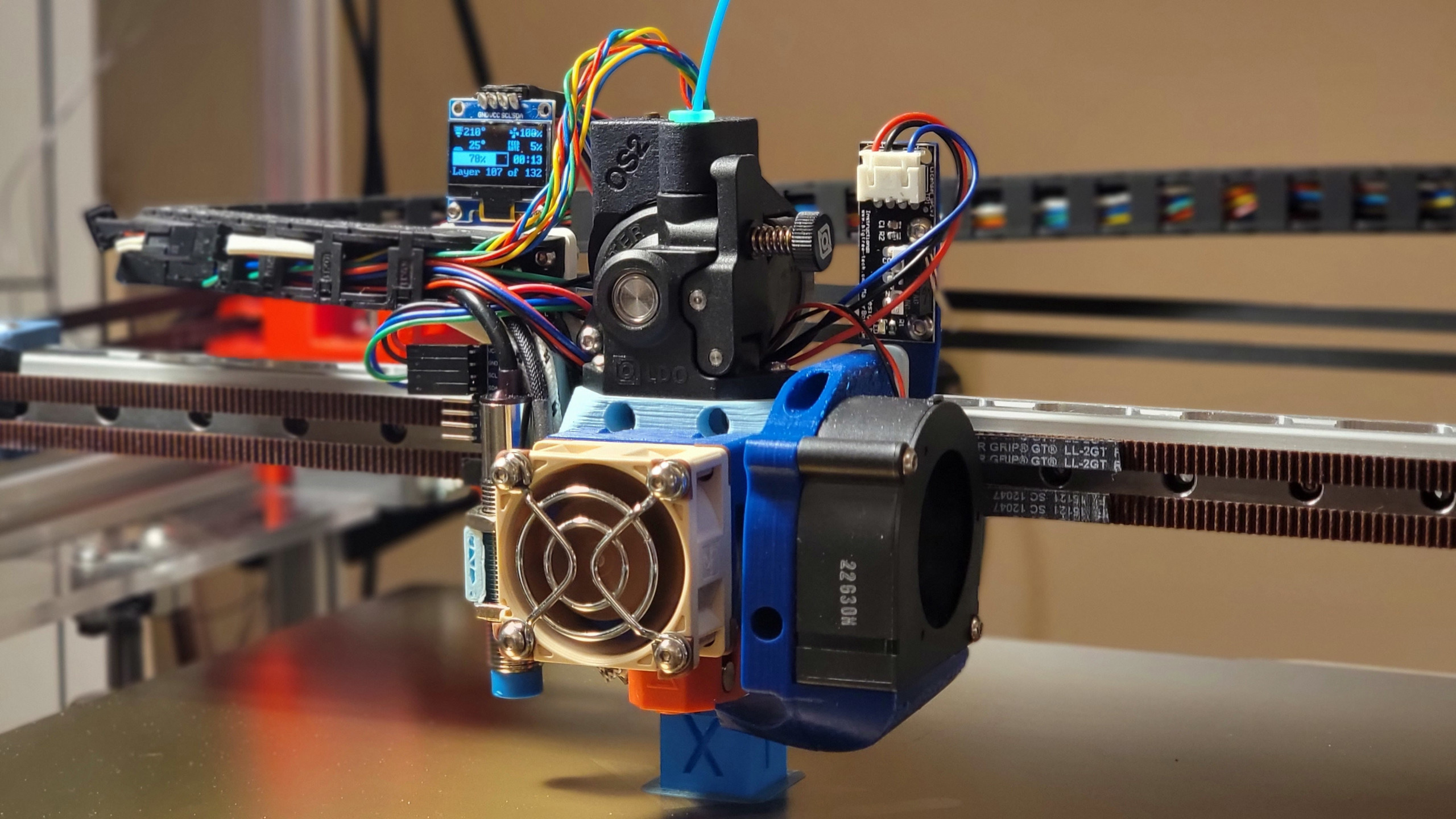

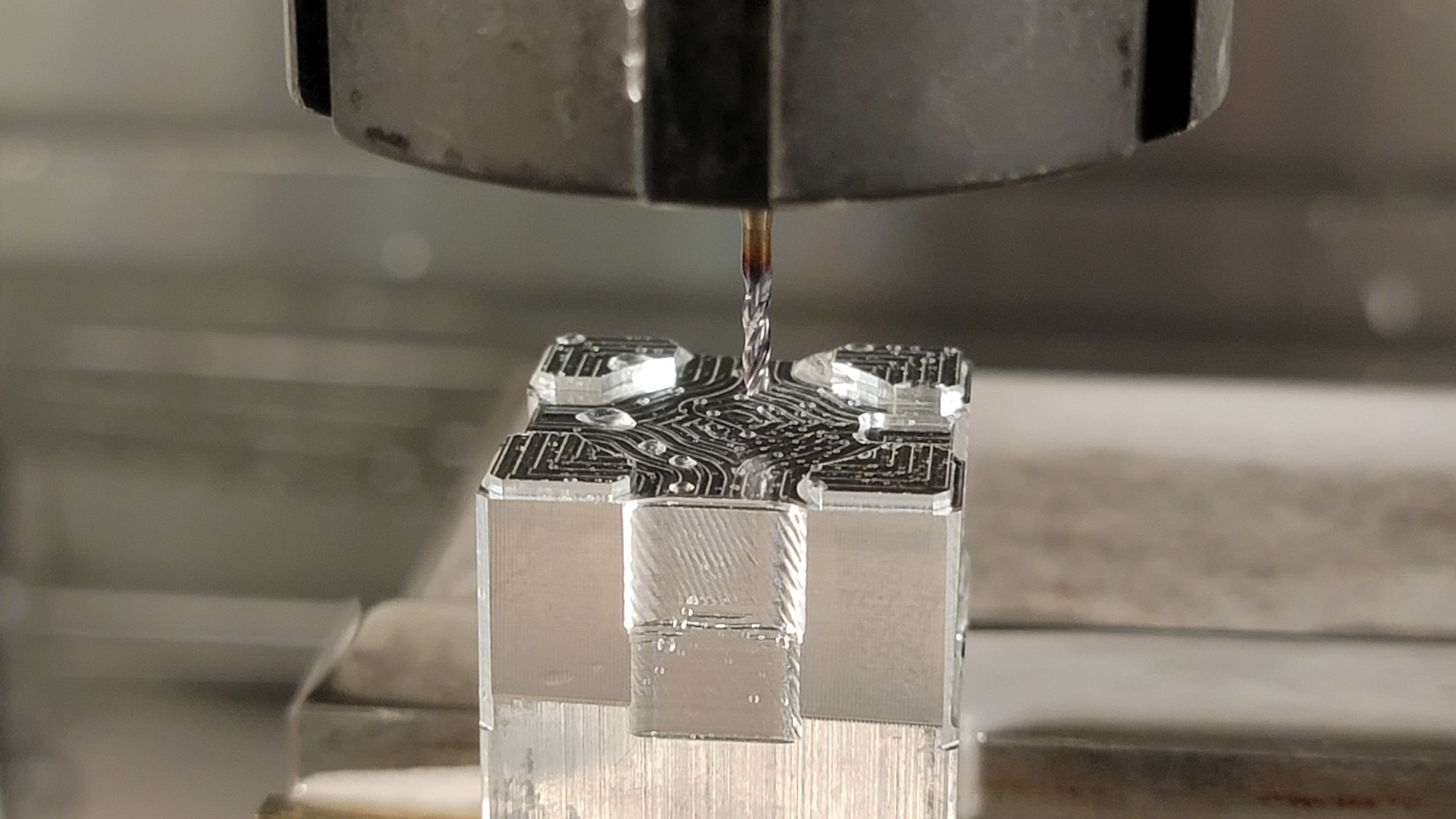

FLICKER MK2

My custom personal printer. Enhanced precision with a machined aluminum bed, full-aluminum frame, and acrylic enclosure. Now capable of 2.7 G acceleration and printing large ASA parts with zero warping.

- CNC Machining

- Laser Cutting

- 3D Printing

T-School Taiwan

For 7 weeks, I worked in a 4-person team to conduct an on-site evaluation of the new Talent School program at Soochow University in Taipei, Taiwan.

- Experiential Learning

- Program Evaluation

- Cross-Cultural Collaboration

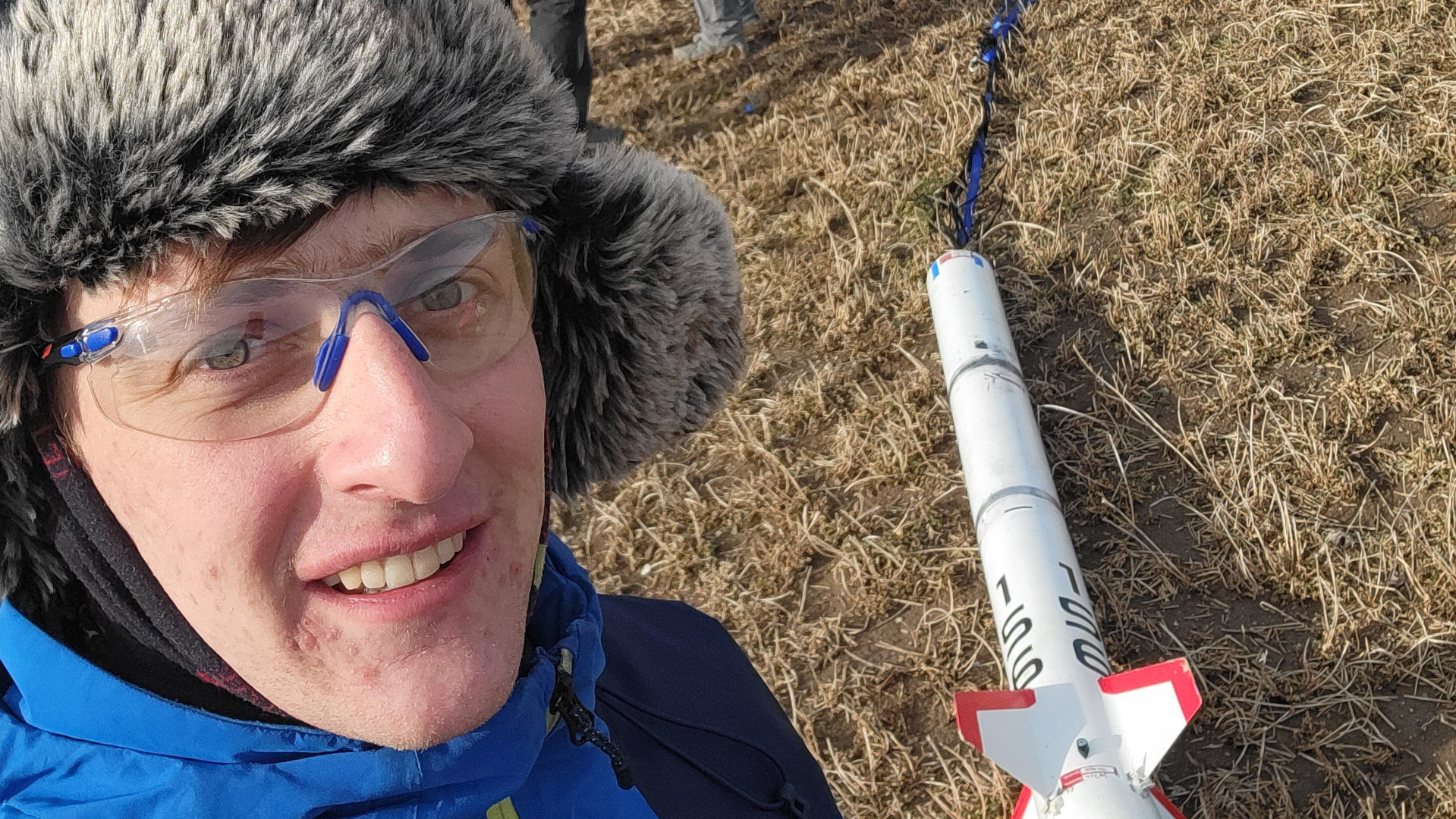

HPRC Test Launch

Assembled reusable joints and ensured system integrity for a 12-foot rocket, contributing to a successful high-power test launch in the northern USA.

- Aerospace Engineering

- High-Power Rocketry

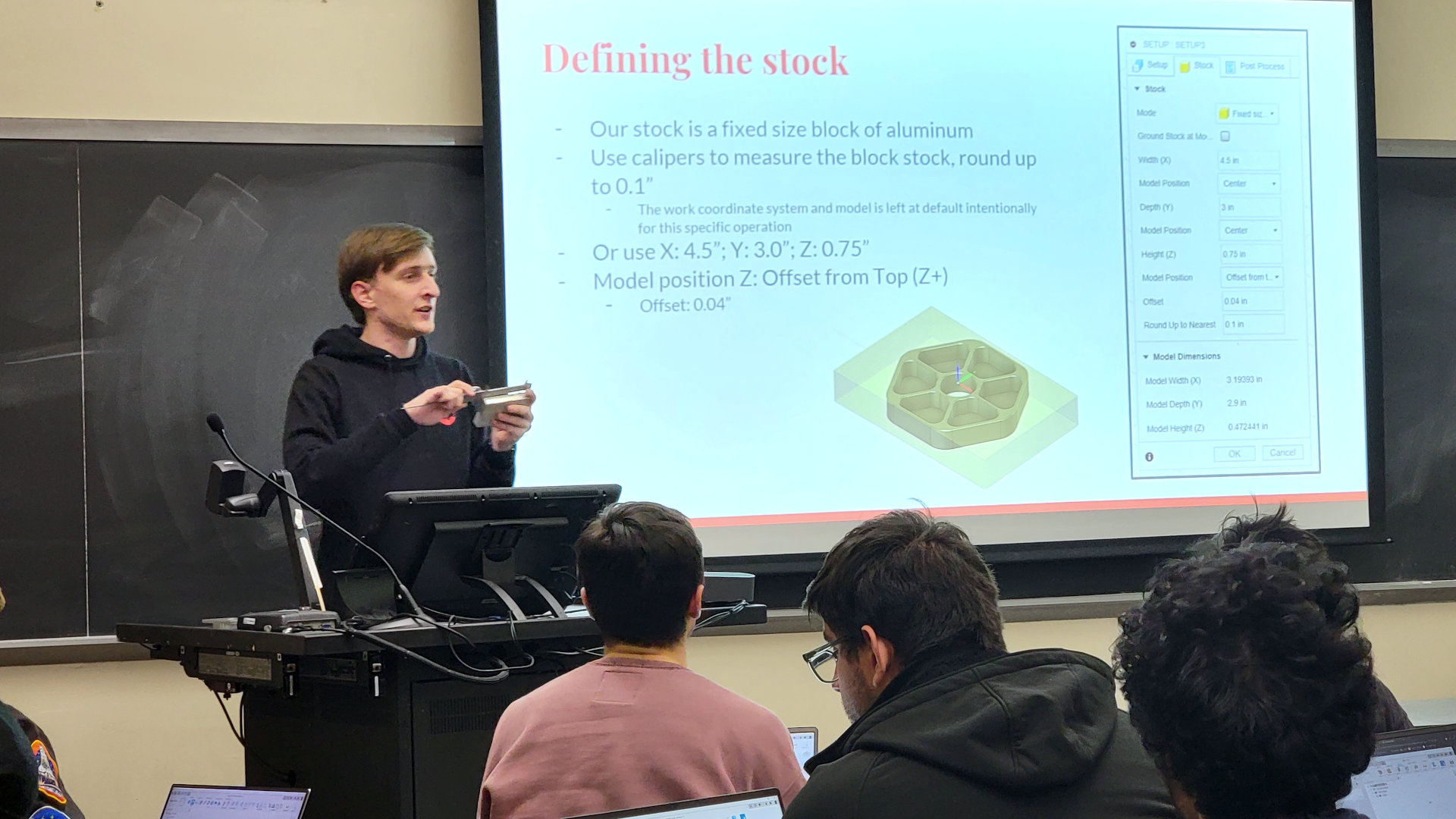

Teaching

I have taught CNC machining and CAM at Washburn Machine Shops for over 3 years, ultimately developing a three-part workshop series on mill machining fundamentals.

- Teaching

- CNC Machining

- Workshop Development

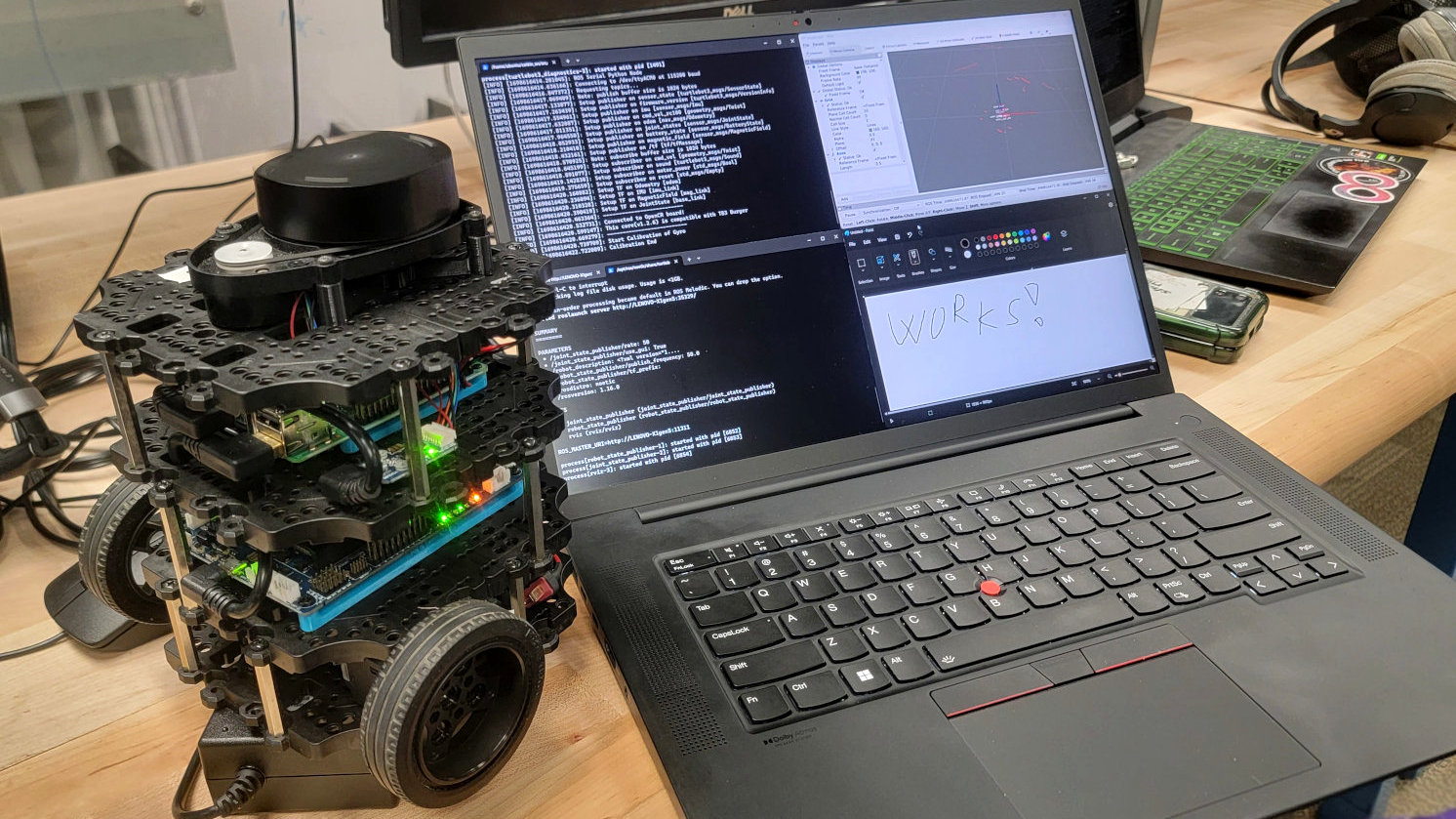

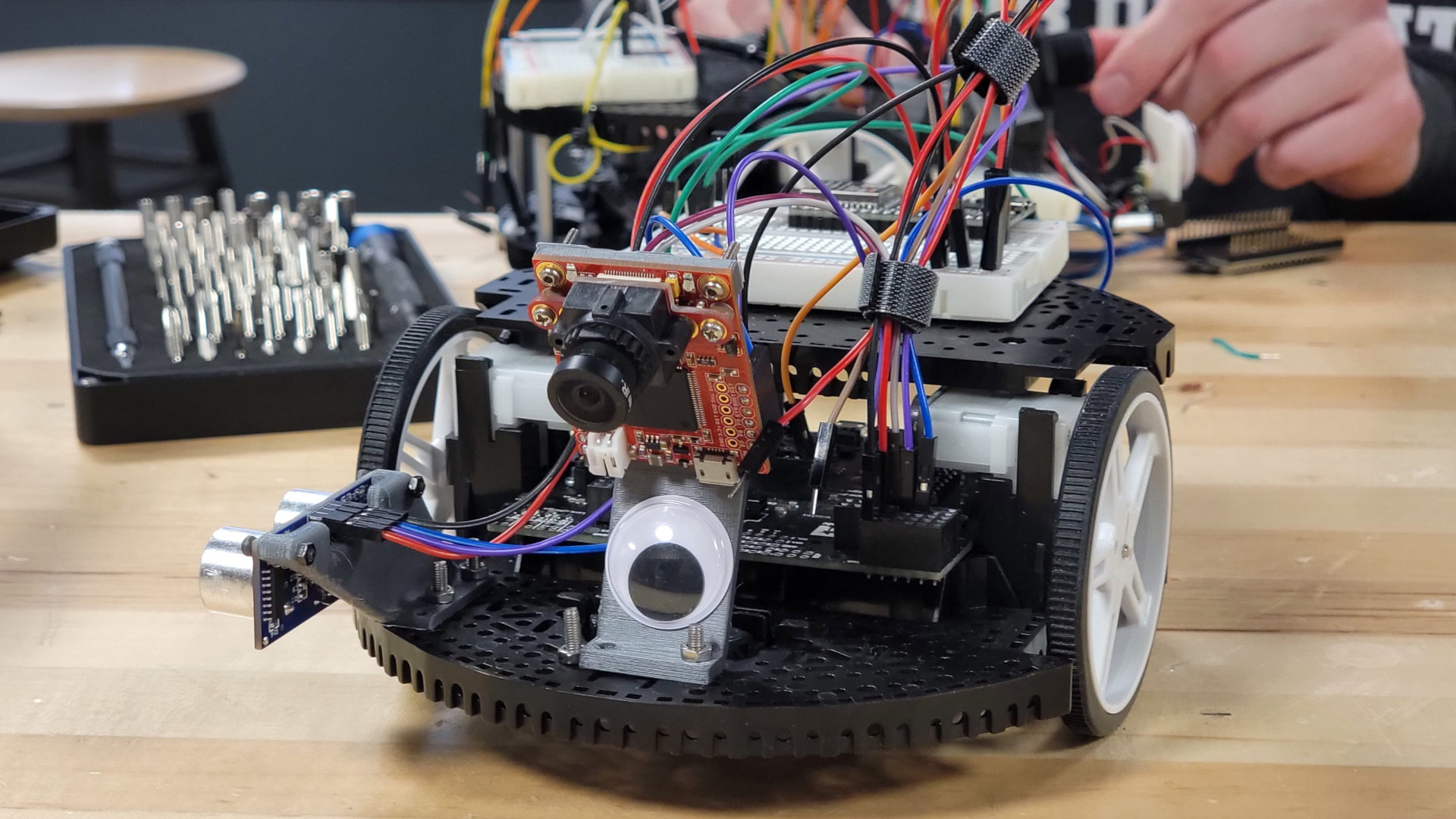

RBE3002

In this course I learned about the Robot Operating System (ROS), understood basic Simultaneous Localization and Mapping (SLAM) and Augmented Monte Carlo Localization (AMCL), and used all to navigate a robot autonomously through a maze, with time and walls being the only obstacles.

- ROS

- SLAM

- Navigation

- Linux

Whirly Tunes

Precisely spinning 80s children's toys to produce unique sounds that lie somewhere between a choir, an organ, and an angry ceiling fan. In a four-person team we created a machine that blends auditory and visual art making a fine addition to the WPI Musical Robotics Lab.

- MIDI

- Raspberry Pi

- Python

Industrial Robotics

Mastering serial and parallel manipulator kinematics in MATLAB, I delved into the intricacies of typical serial robot arms, delta robots, and Gough–Stewart platforms.

- MATLAB

- 6-DOF serial manipulators

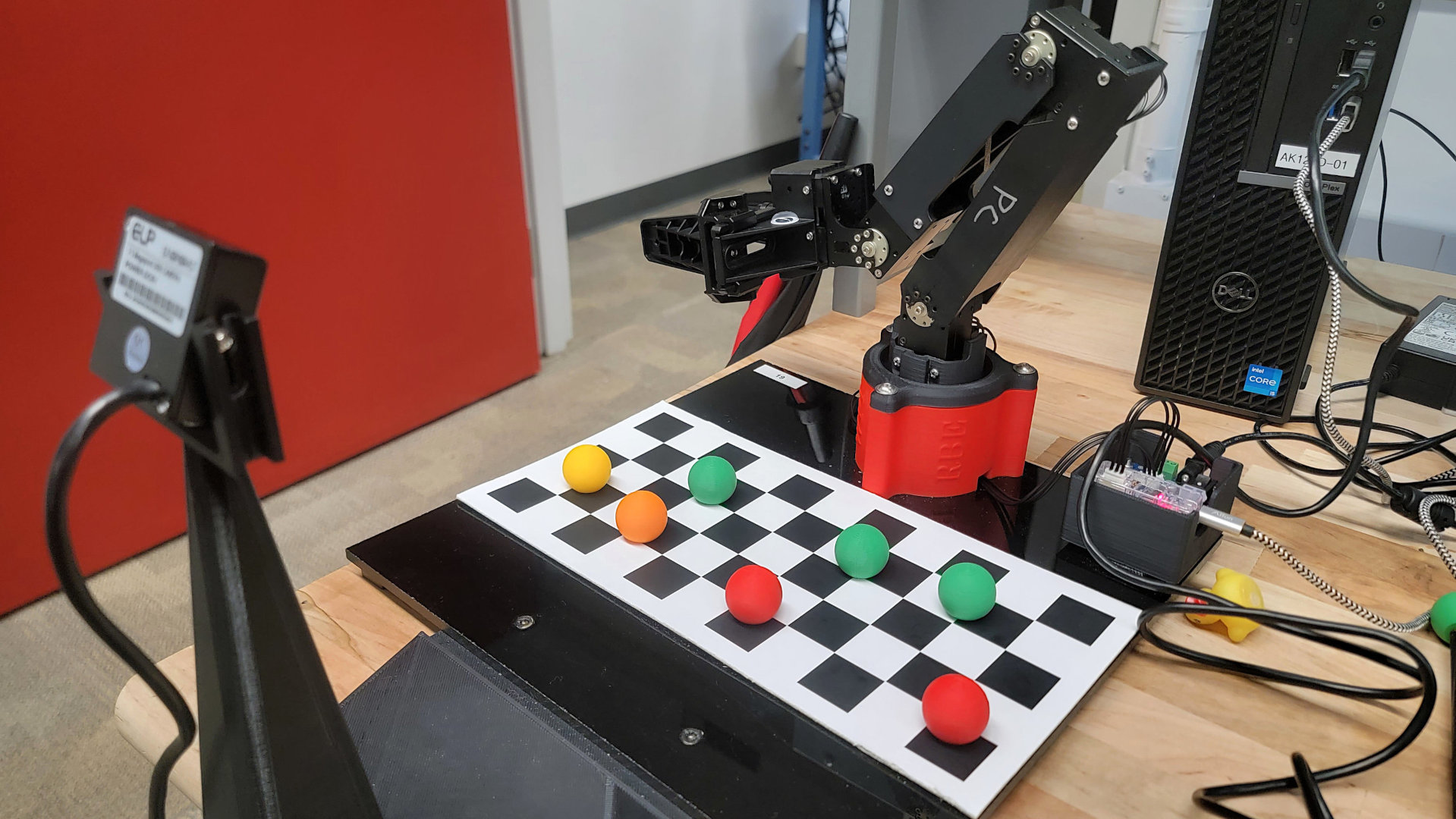

RBE3001

In 7 weeks I coded a 4-DOF arm with forward, inverse, differential, and velocity kinematics. The arm is capable of sorting colored balls autonomously using computer vision.

- MATLAB

- OpenCV

- Linux

FLICKER

Introducing FLICKER: My custom 3D printer with a 30×30×40 cm volume, inspired by the Aperture Science aesthetic. Designed for quiet, high-speed printing, it features a mix of 3D printed parts, a custom-machined aluminum beam, and laser-cut components.

- SolidWorks CAD

- 3D Printing

- Klipper Firmware

- CNC Machining

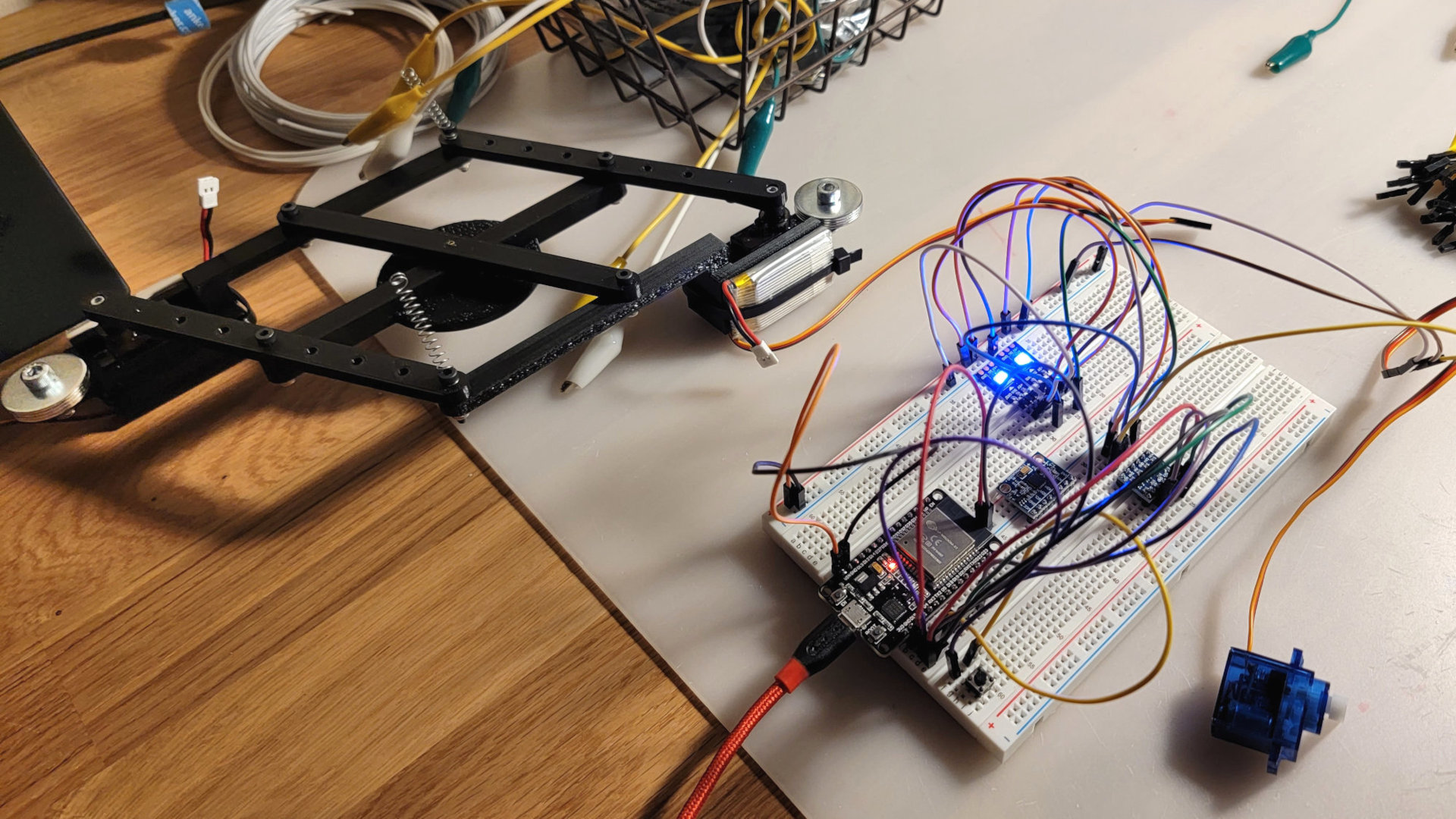

ShiveWorks

A dynamic material research project at WPI, utilizing individually or collectively actuated segments to explore wave propagation. The demonstrational device consists of up to 100 segments. All to help validate mathematical results and simulations.

- Python

- MQTT

- ESP32

- C++

RBE 2002

Synchronized three robots over WiFi to collaboratively solve an escape room puzzle, applying foundational principles of robotics engineering, including sensor interaction and fusion, feedback, and decision processes.

- C++

- MQTT

RBE 2001

Designed and built an autonomous robot to exchange a solar panel on a roof using minimal sensors and a four-bar linkage system. Leveraged rapid prototyping techniques, including 3D printing and laser cutting, to optimize the design within a tight timeframe.

- CAD

- 3D Printing

- Laser Cutting

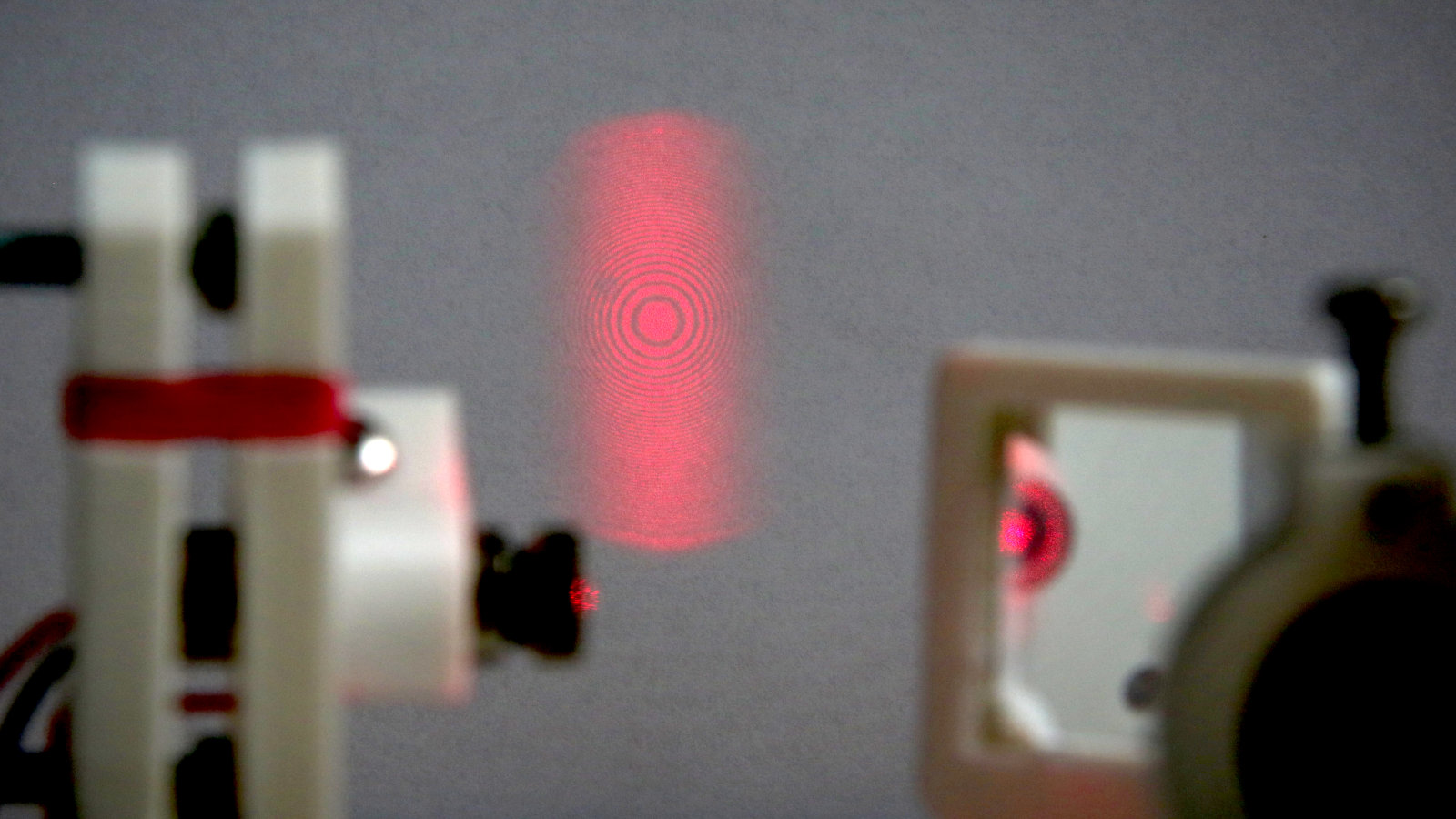

LEGO Interferometry

Designed and built a low-cost Michelson interferometer using LEGO and 3D-printed components, achieving light interference, presenting at a physics conference, and publishing the results in a national physics journal.

- Light Physics

- Teaching

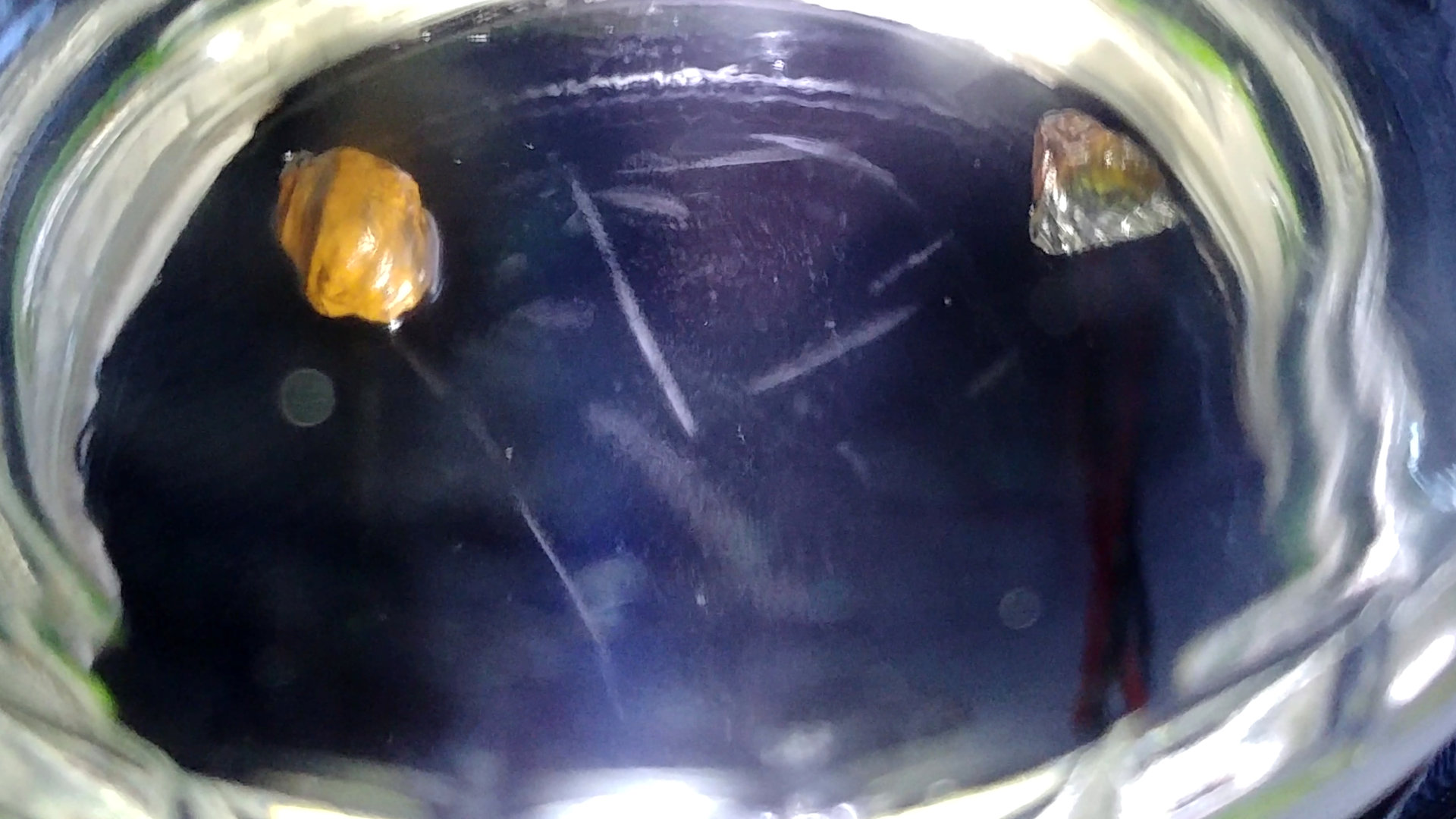

Cloudy with Particles

In high school, I built a functional cloud chamber to visualize ionizing radiation using a reusable Peltier cooling system, successfully displaying alpha and beta particle trails.

- Nuclear Physics

- Heat Transfer

- Peltier Cooling