Project FLICKER MK1

What is FLICKER ?

At my university, I had access to a 3D printer farm. It sounded like a dream come true, but reality painted a different picture. The queue was long, and the material options were limited to PLA. Worst of all, the print quality was awful. The parts were just unusable. So the hunt began. I embarked on a mission for a 3D printer that looked cool, didn't cost a fortune, and, to top it off, I wanted to customize it to my liking. But let me tell you, after two weeks of browsing the internet, I could not find anything that would be up to my standards. So, I decided to take matters into my own hands and engineer one. That's how FLICKER came to life, and it's everything I've ever wanted in a 3D printer, and a project to tinker with whenever I've got time.

The acronym stands for Fast Linear Inductive CoreXY Kinematic Efficient Replicator. FLICKER is a personal 3D printer project, built from the ground up in the Aperture Science Laboratories aesthetic, and featuring a generous 30x30x40 cm print volume. Designed for quiet operation and high-speed 3D printing, it is built mostly out of 3D printed parts, a custom machined aluminum beam, and many laser-cut components.

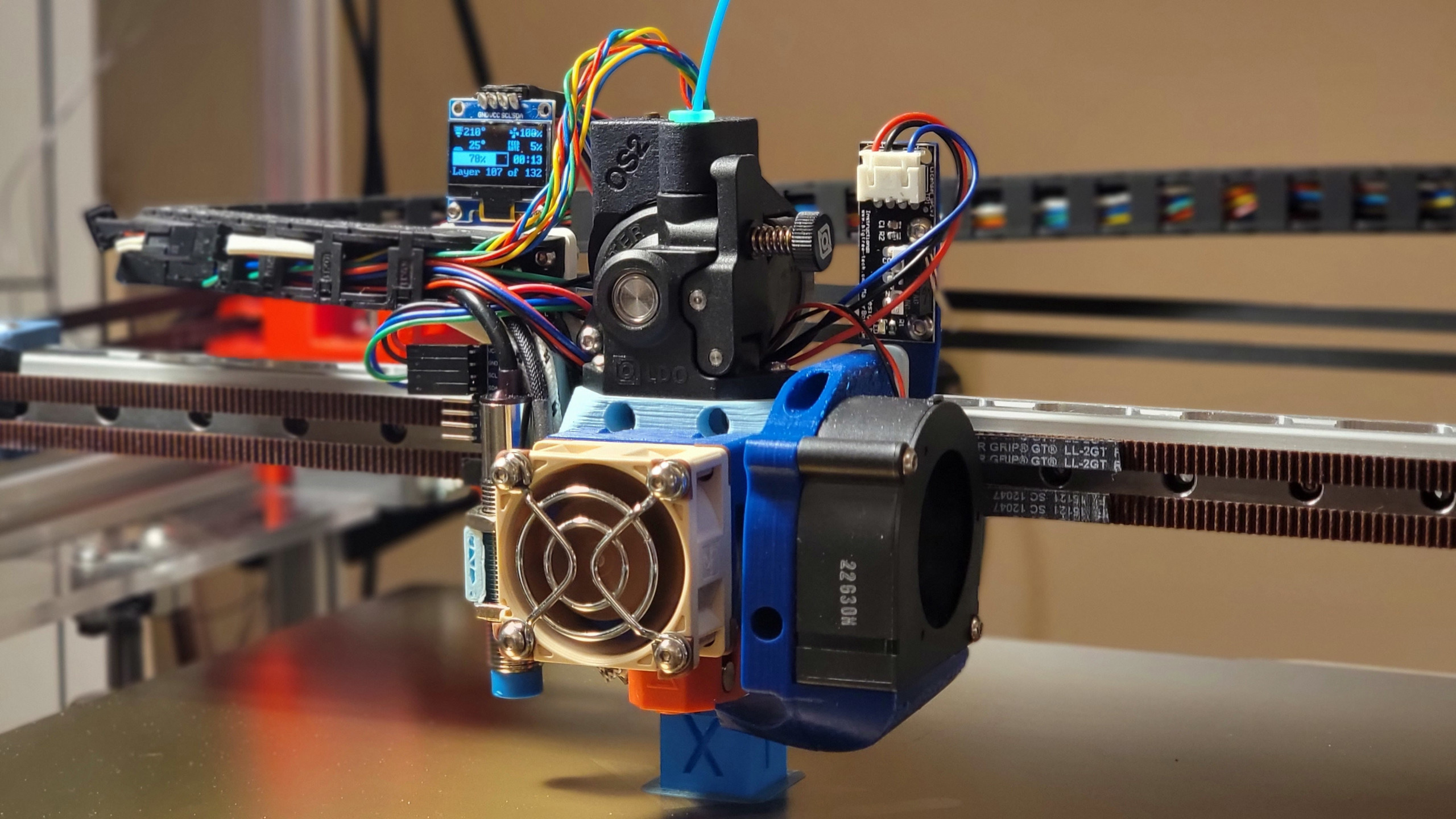

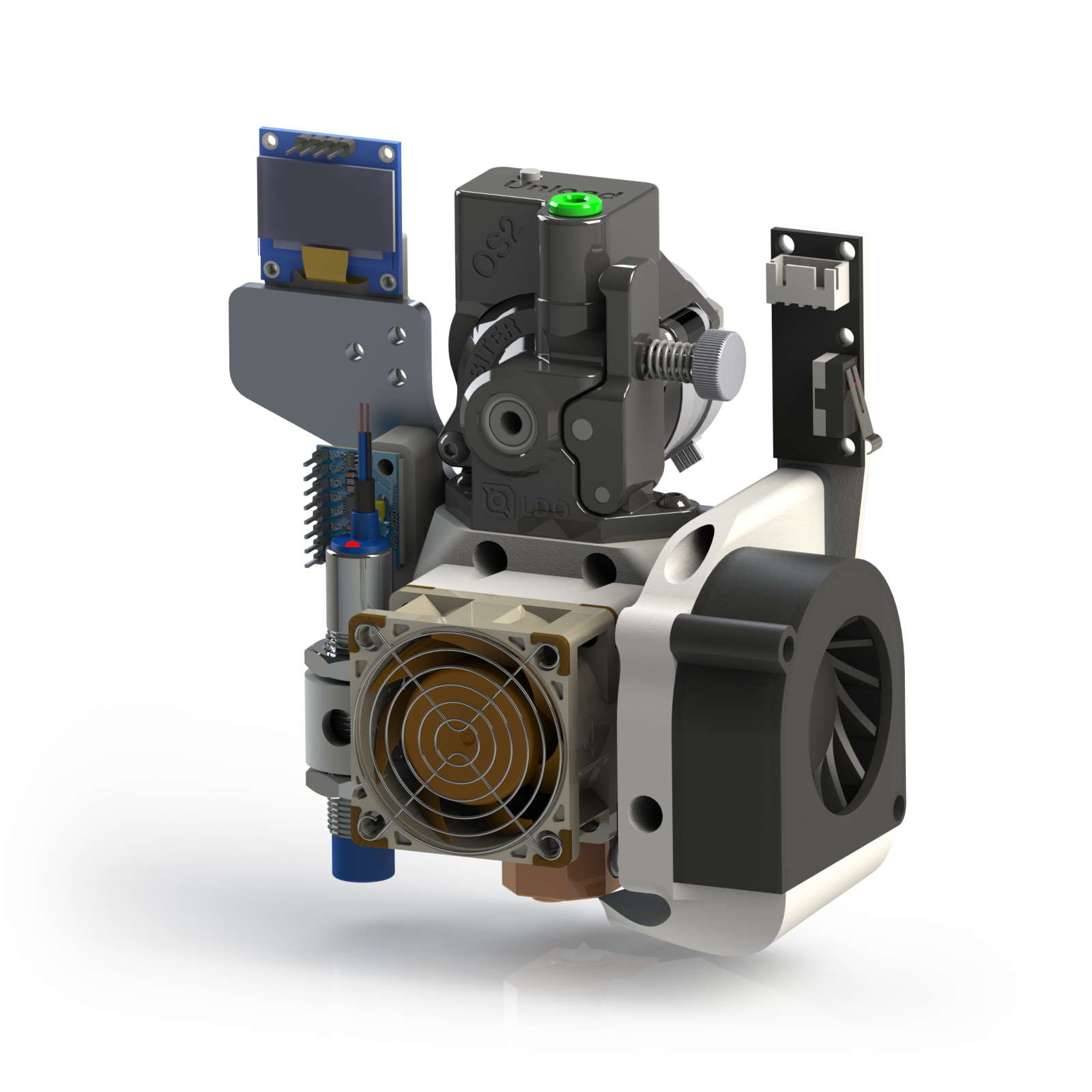

FLICKER print head

Print head render

FLICKER includes a few off-the-shelf components, like the Phaetus Dragon SF hotend, the LDO Orbiter v2.0 extruder, and a tiny OLED display purely for the cool factor. Most other parts are my design and are 3D printed from PLA, with plans to reprint them using ASA on FLICKER itself.

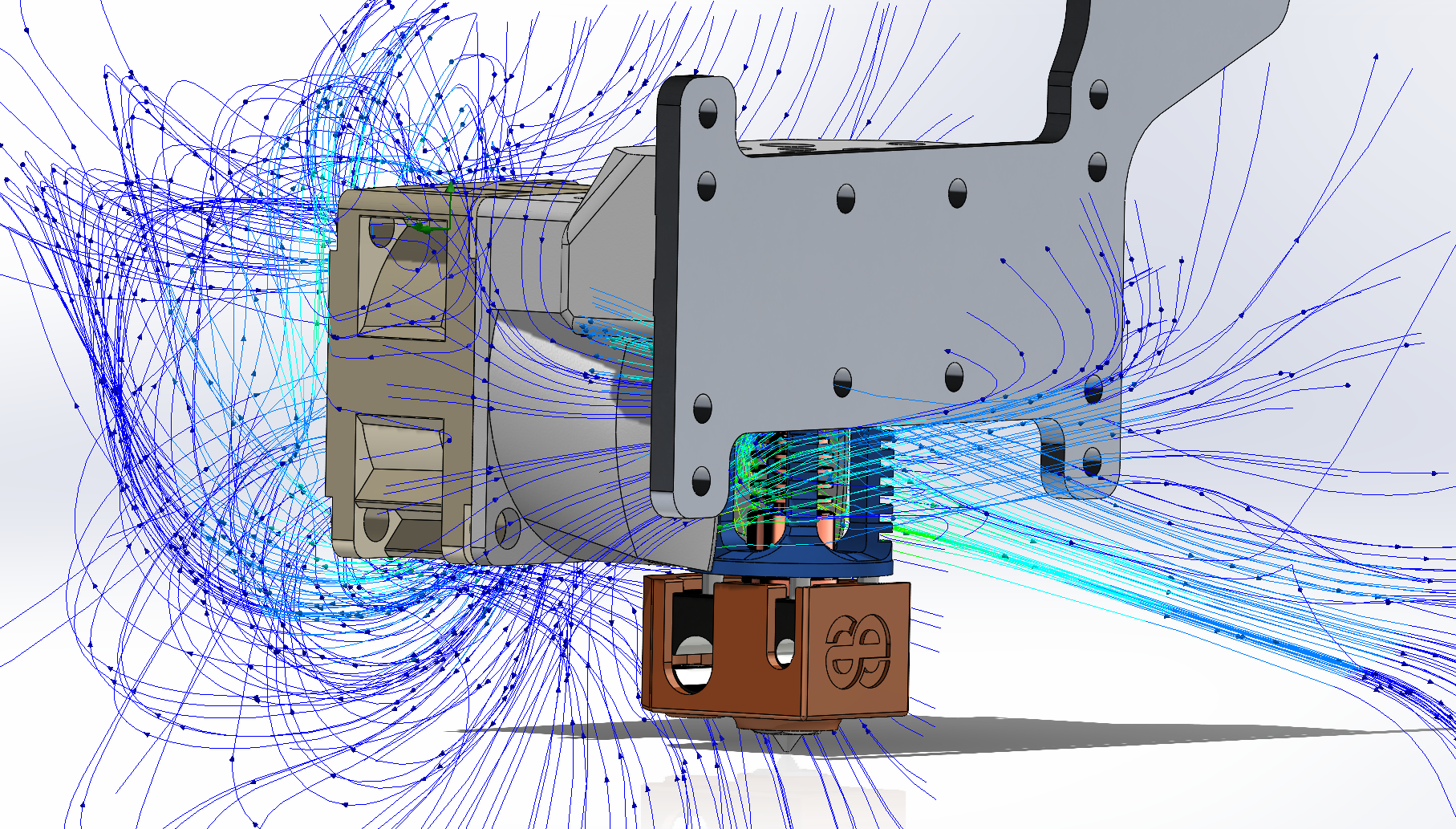

Hotend cooling CFD

I even ran some CFD analysis to ensure the hotend has enough airflow to prevent the plastic mounts from melting at 350°C.

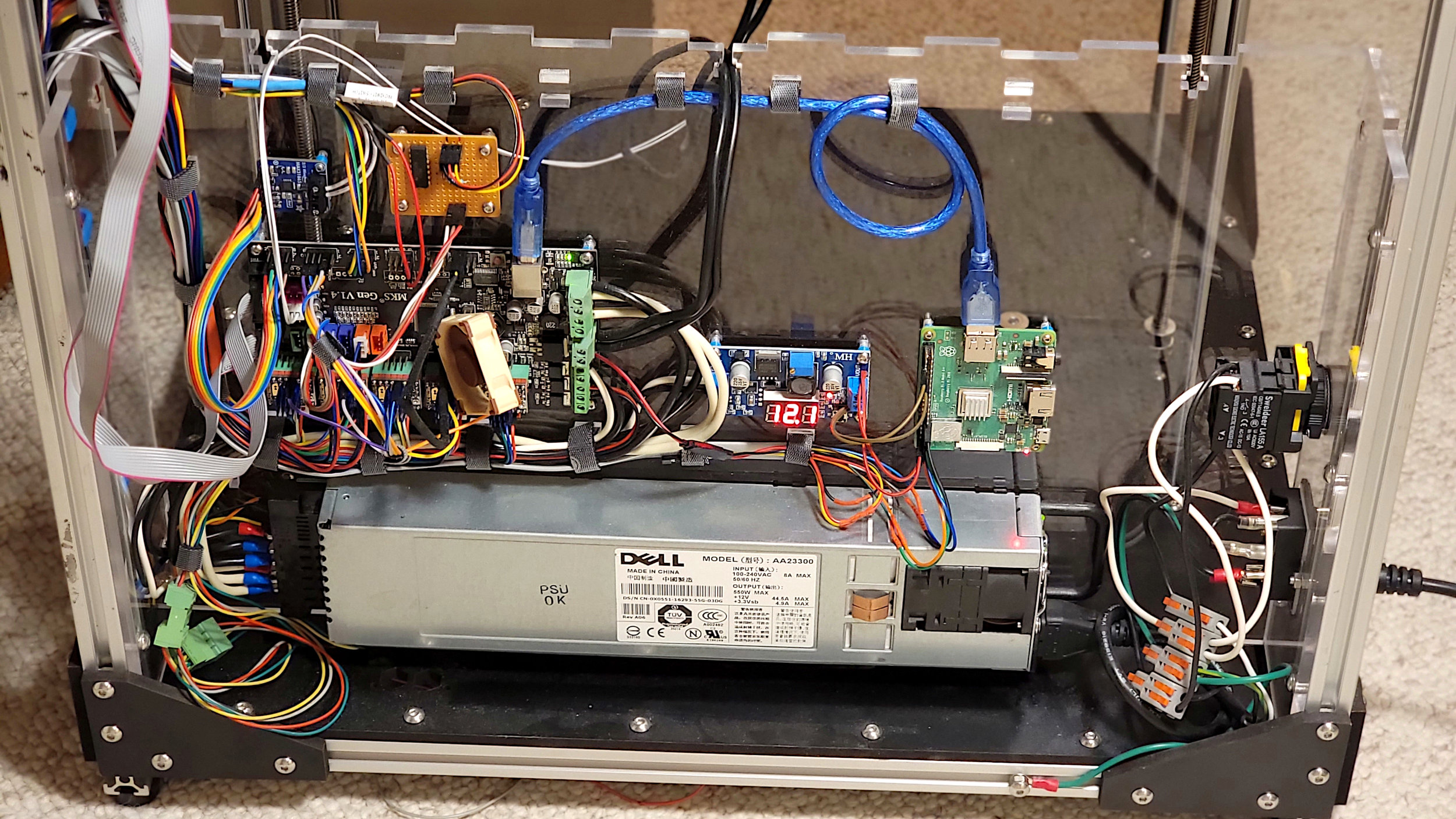

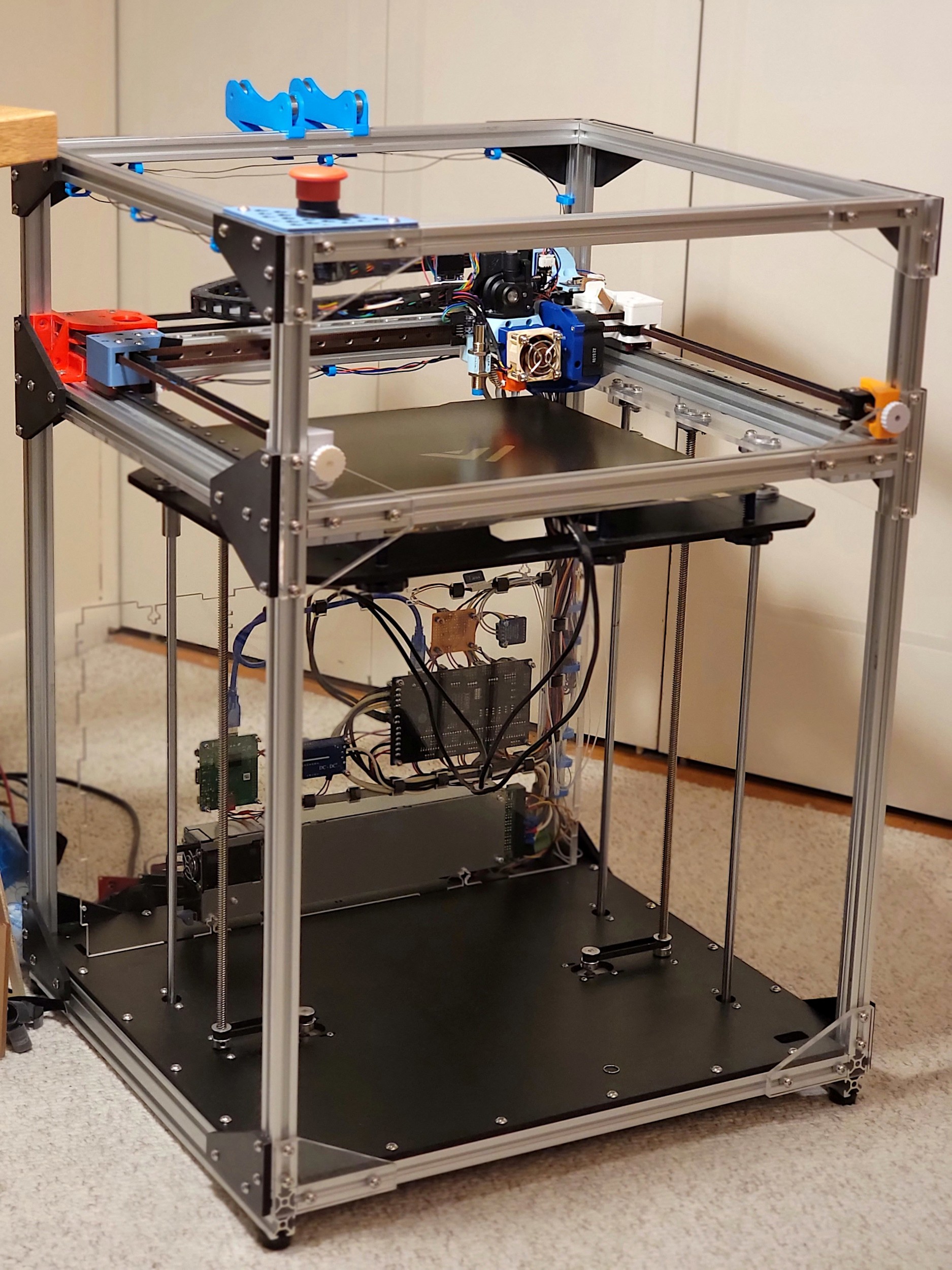

The jerry rigged electronics powering this bad boy

And here it is - the full shebang! This is FLICKER in all its glory. It's not just a machine; it's a work of art (and my first fully custom 3D printer).

Complete tall printer

FLICKER in action. My first large scale project.