Project FLICKER MK2

Harder, Better, Faster, Stronger

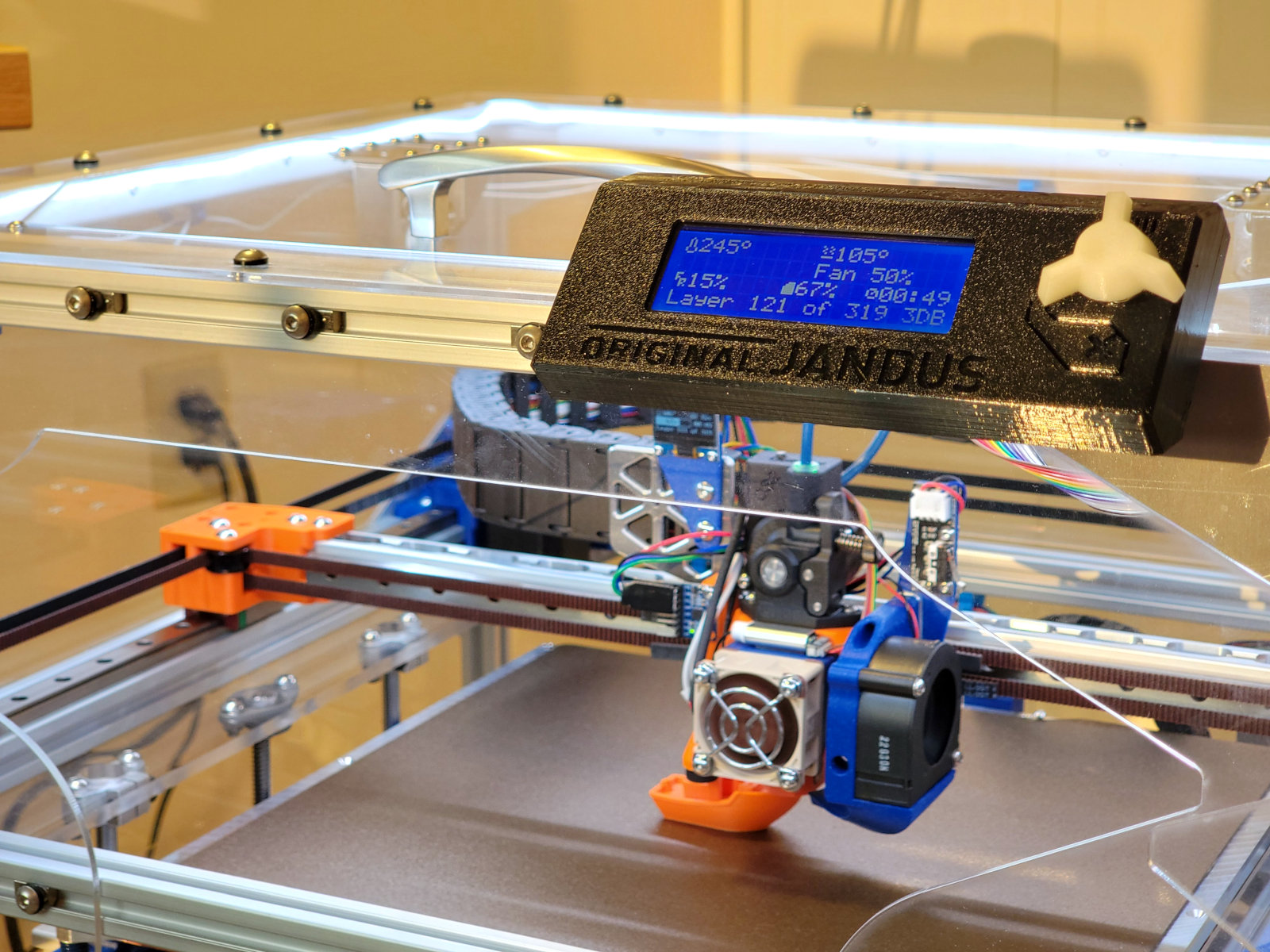

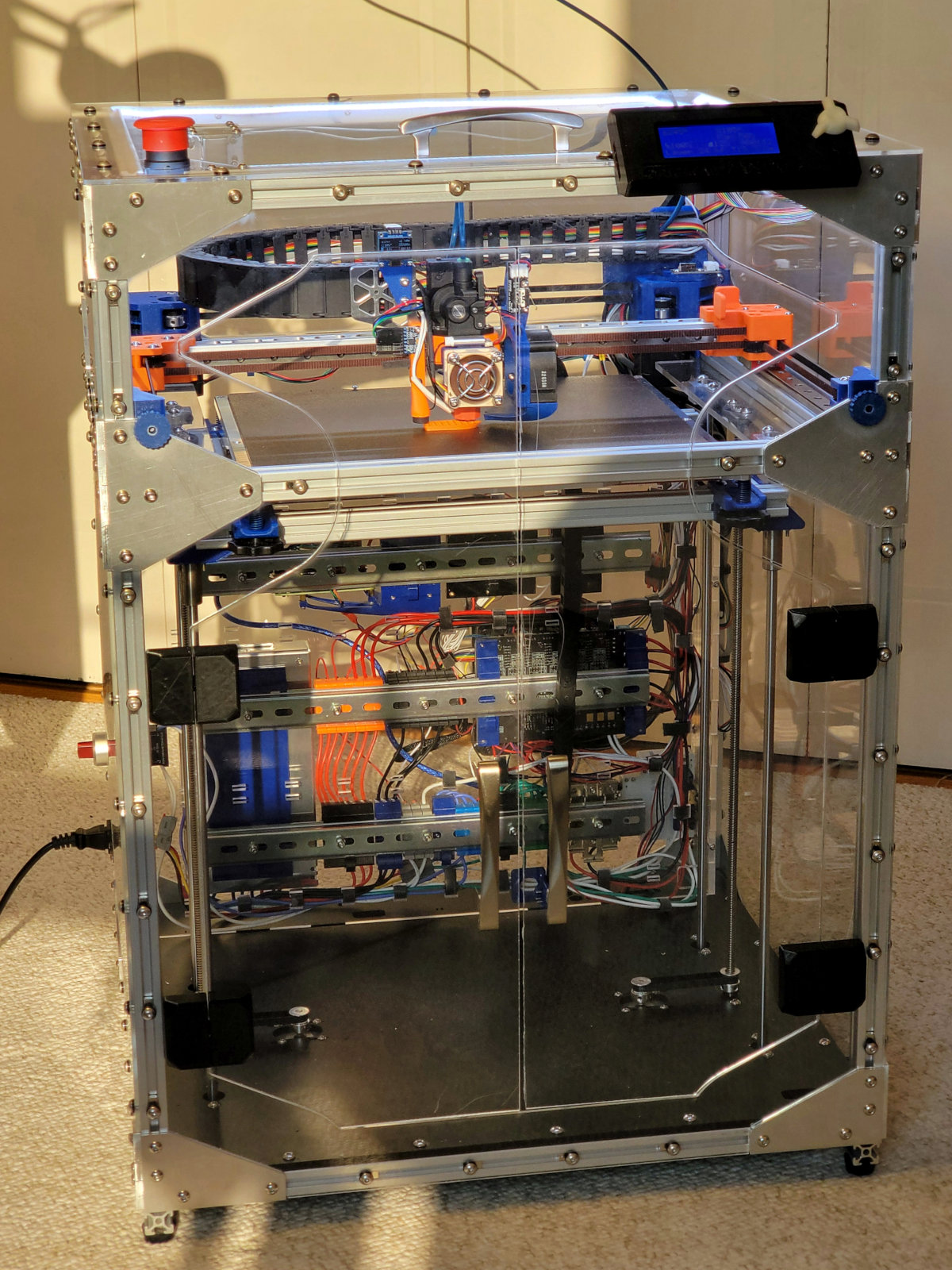

The ultimate 3D printer project, FLICKER MK2, is a custom-built 3D printer designed for speed and precision. After a year of hard work, it's now in its second iteration and better than ever.

Click here to see the MK1It comes with long-awaited upgrades: ASA 3D-printed parts, 32-bit controller board, AC heat bed, full-aluminum frame, 50 watts of RGB LED lights, and a custom acrylic enclosure.

Insane speeds: 27000 mm/s^2 acceleration, 300 mm/s print speed, 600 mm/s travel speed here

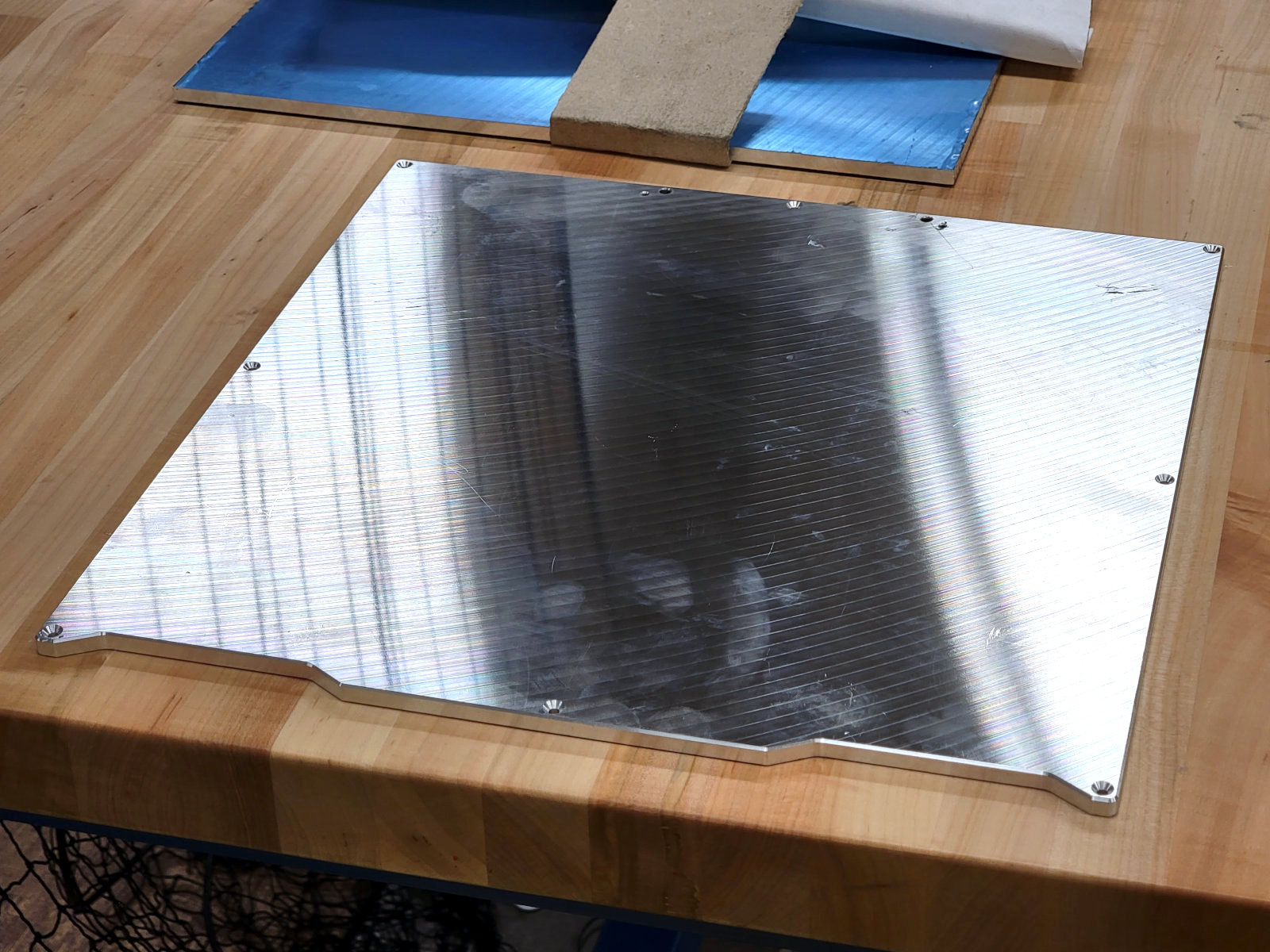

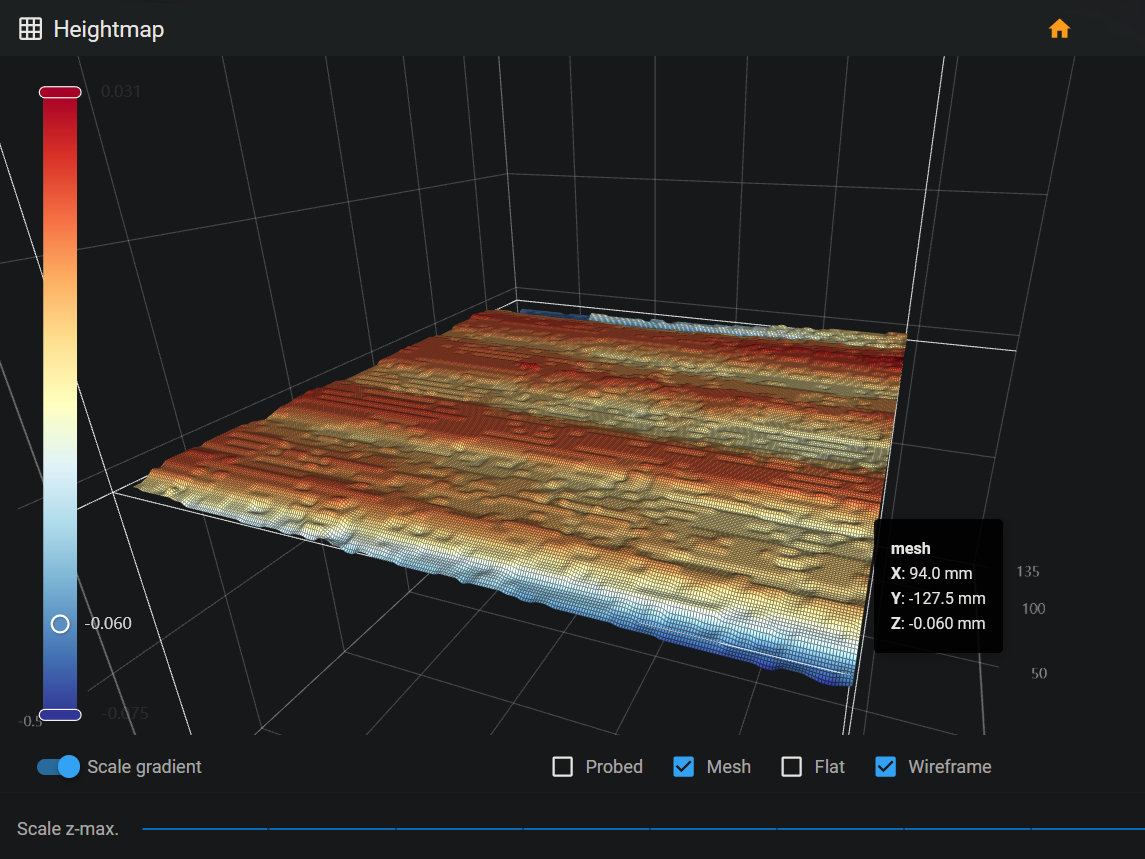

Designed to be a personal printer that can handle most materials thrown at it, FLICKER MK2 is a versatile machine that can print anything from PLA to ASA with virtually zero warping. First layer adhesion is achieved with a custom-machined aluminum bed boasting just 0.004" or 0.1mm variation across the surface. The 750W AC heater can bring the bed to 105°C in under three minutes.

Custom machined aluminum bed – flat enough to make any machinist proud

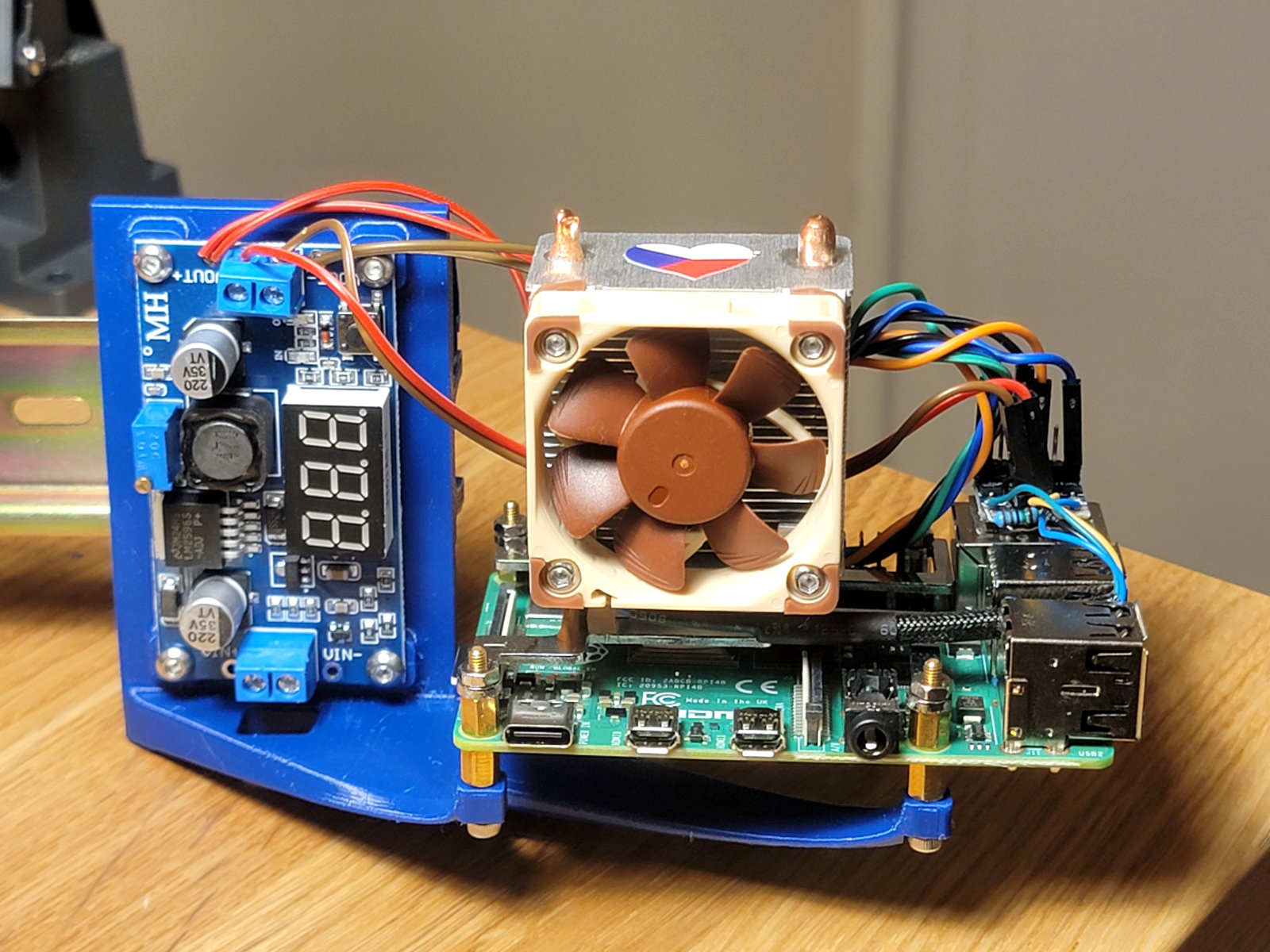

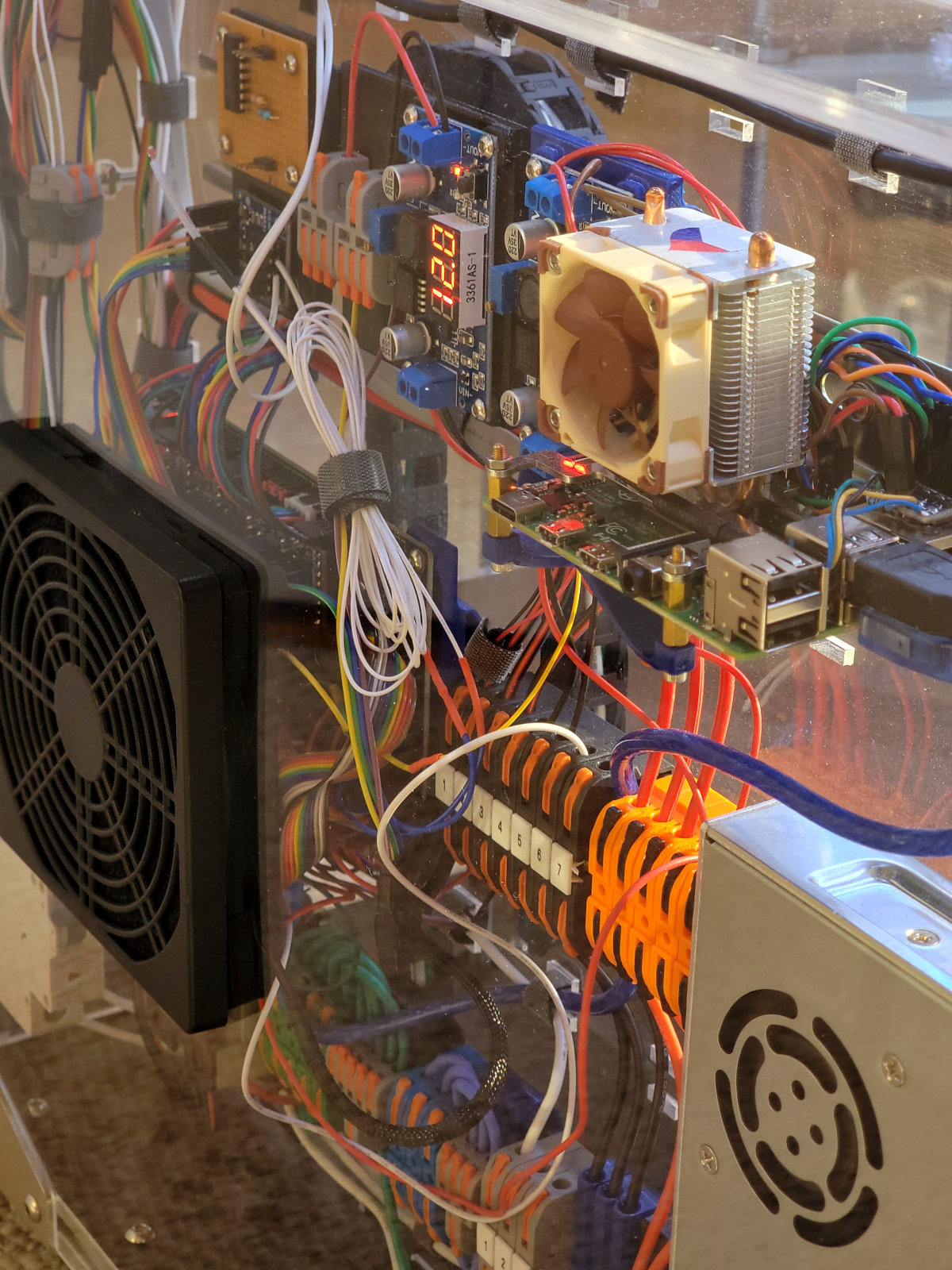

The electronics are organized on DIN rails, making it easy to swap out or upgrade components while keeping things tidy. It also helps with the AC high voltage and 24V DC safety separation. FLICKER MK2 is controlled by a Raspberry Pi 4B+ Compute Module running Klipper firmware, paired with a 32-bit SKR 1.2 Pro controller board and TMC2209 stepper drivers. The result? Smooth 64-microstepping even at 600 mm/s.

Cute RaspberryPi 4B+ compute module, complete with a Noctua tower cooler – because even the hottest tech deserves to be cool

Electronics box with all the goodies

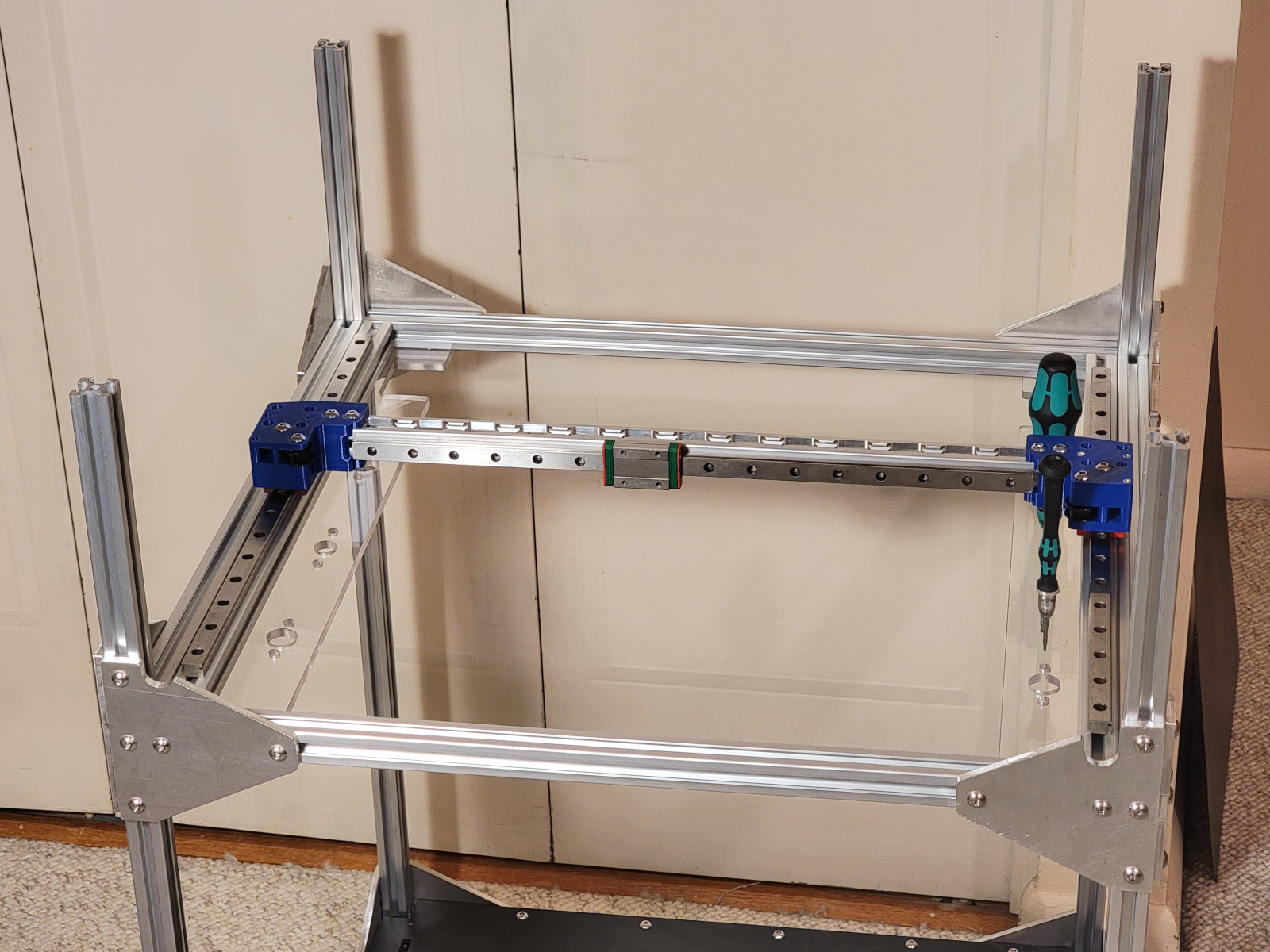

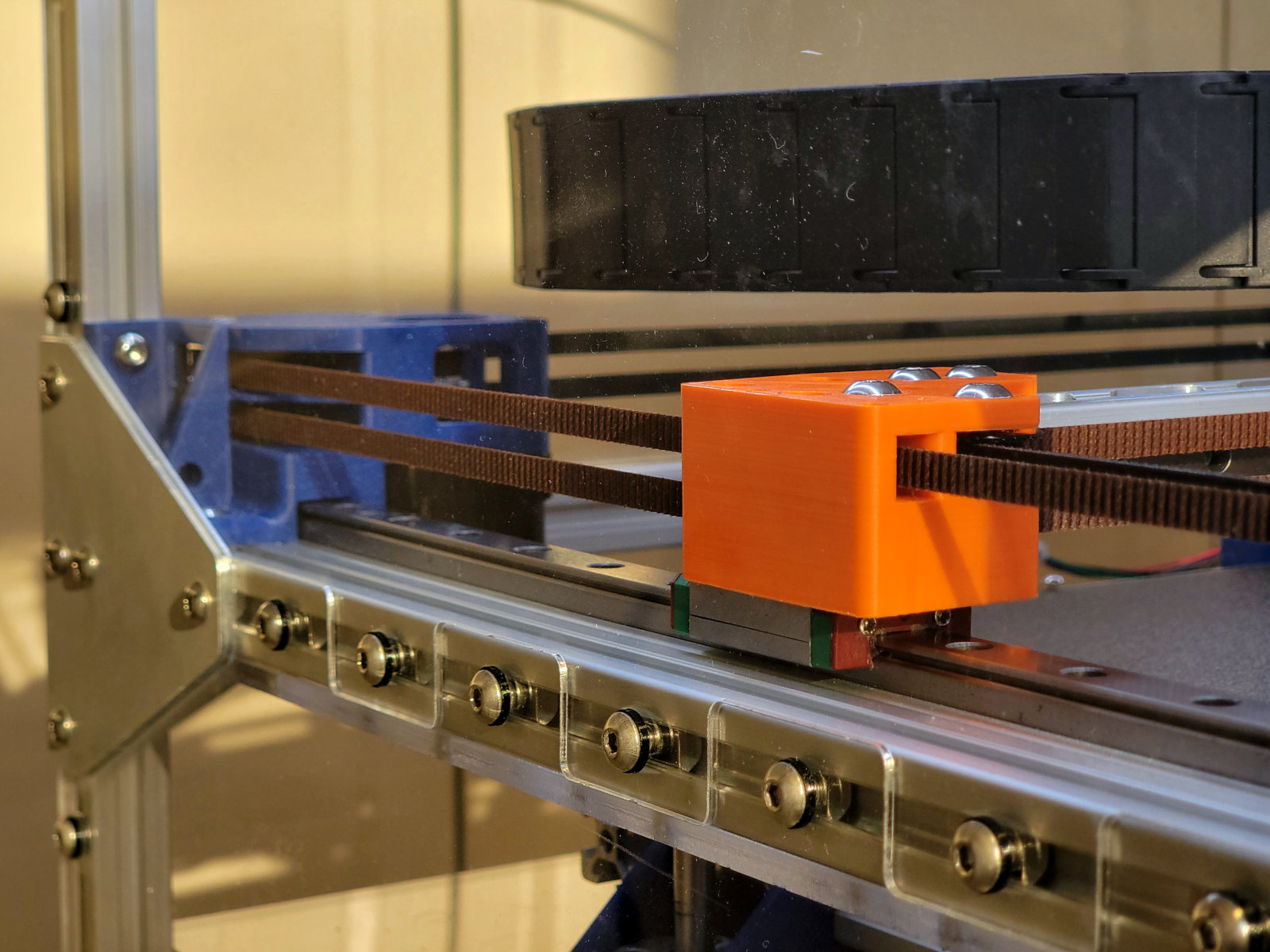

The frame is made out of 20x20mm aluminum extrusions, which in this version are bolted together with custom aluminum brackets. The frame is extremely rigid and can handle the high accelerations and speeds that FLICKER MK2 is capable of.

Full-aluminum frame gantry mid-assembly

A detail of the custom acrylic enclosure panels

The printer is enclosed in a custom acrylic enclosure that keeps the heat in and the noise out. A 120mm fan ensures the electronics stay cool. The enclosure also features front doors and a top lid for easy access.

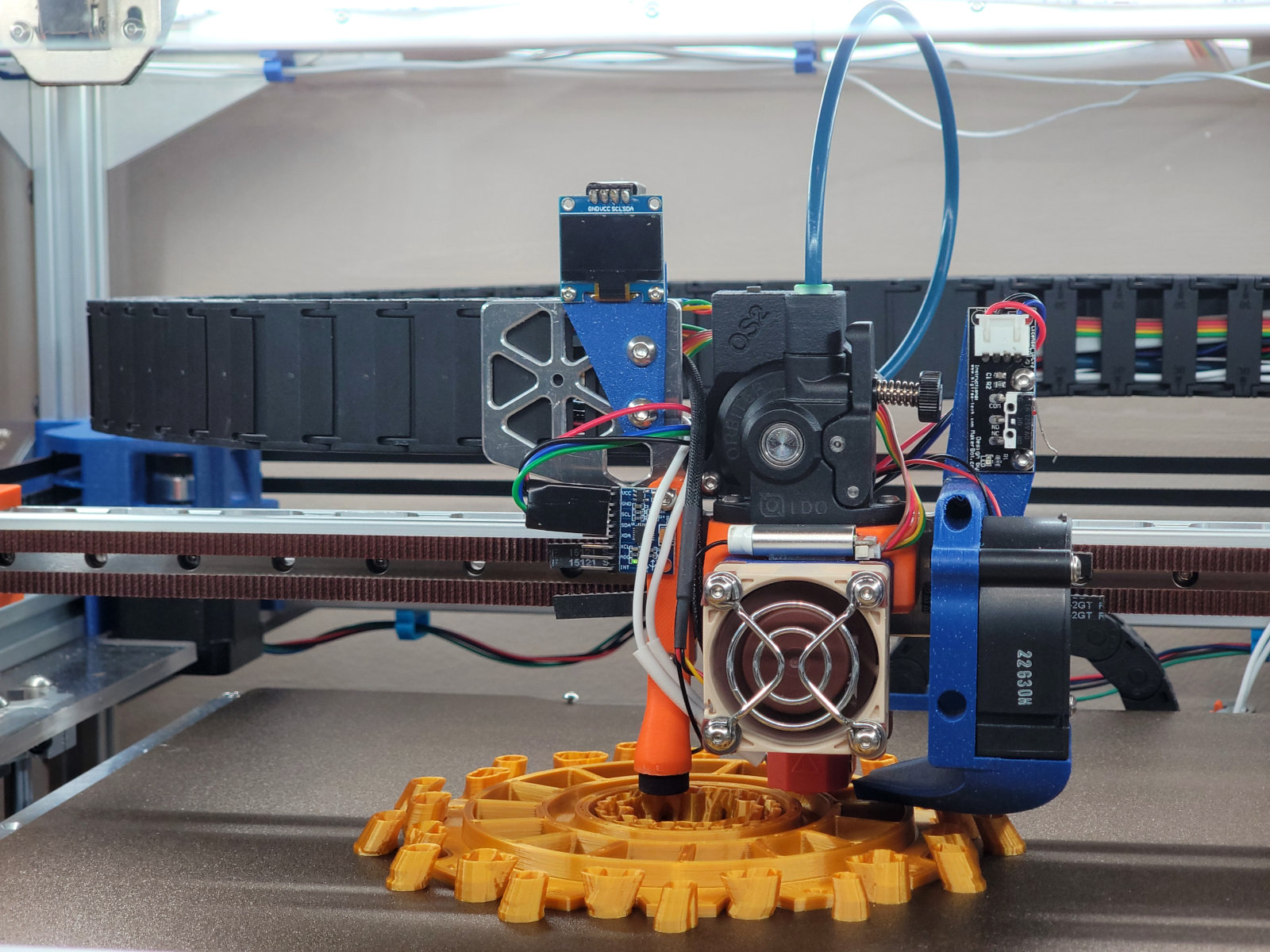

This revision also includes an inductive distance sensor for bed leveling. The bed can now be leveled without moving the nozzle up and down—just a quick side-to-side scan that usually takes under 30 seconds with a 15×15 grid.

Insane bed leveling: 100×100 points probed in under five minutes

A close-up of the printhead doing its thing

An artistic shot during the golden hour

FLICKER MK2 in all its glory