Aluminum companion cube

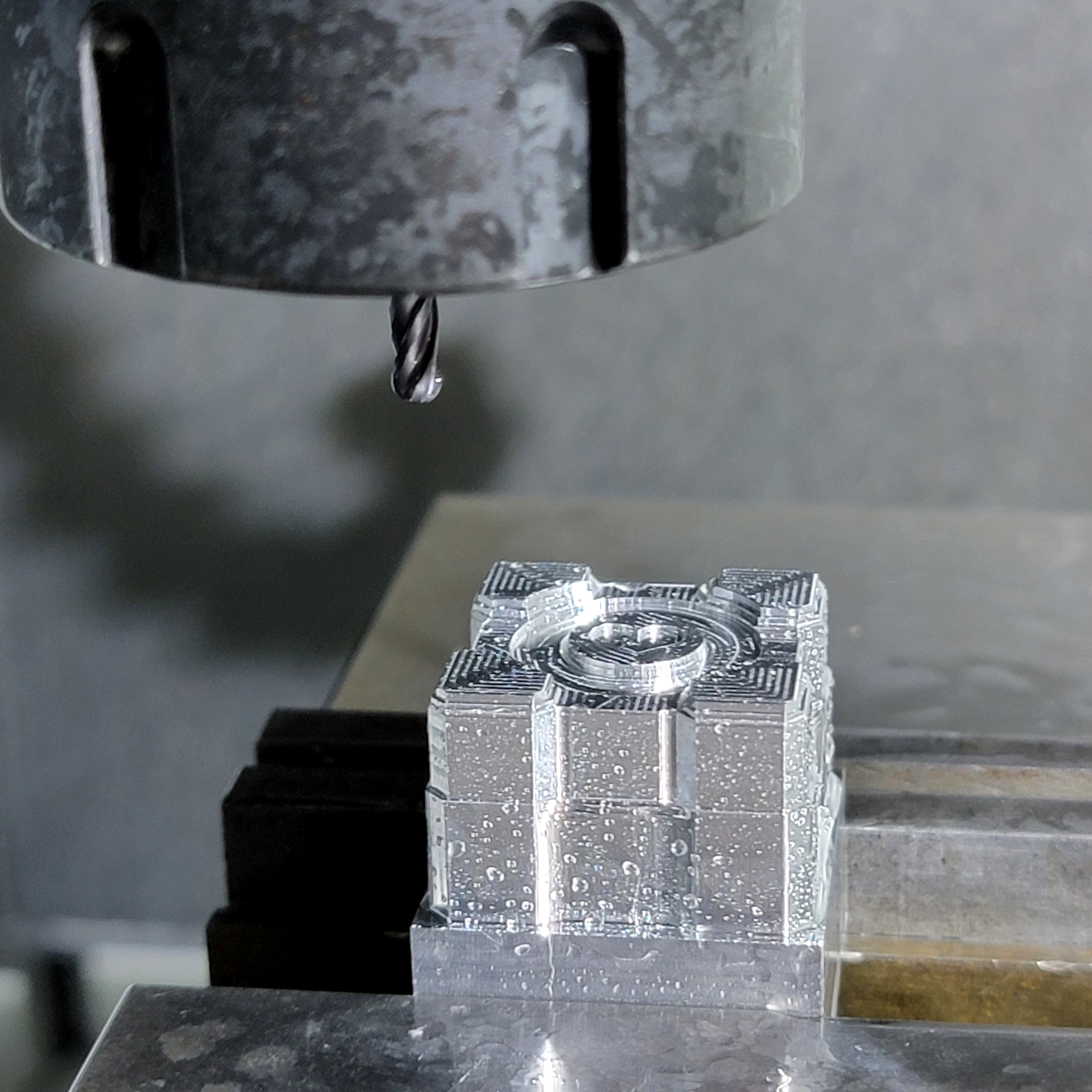

The machining

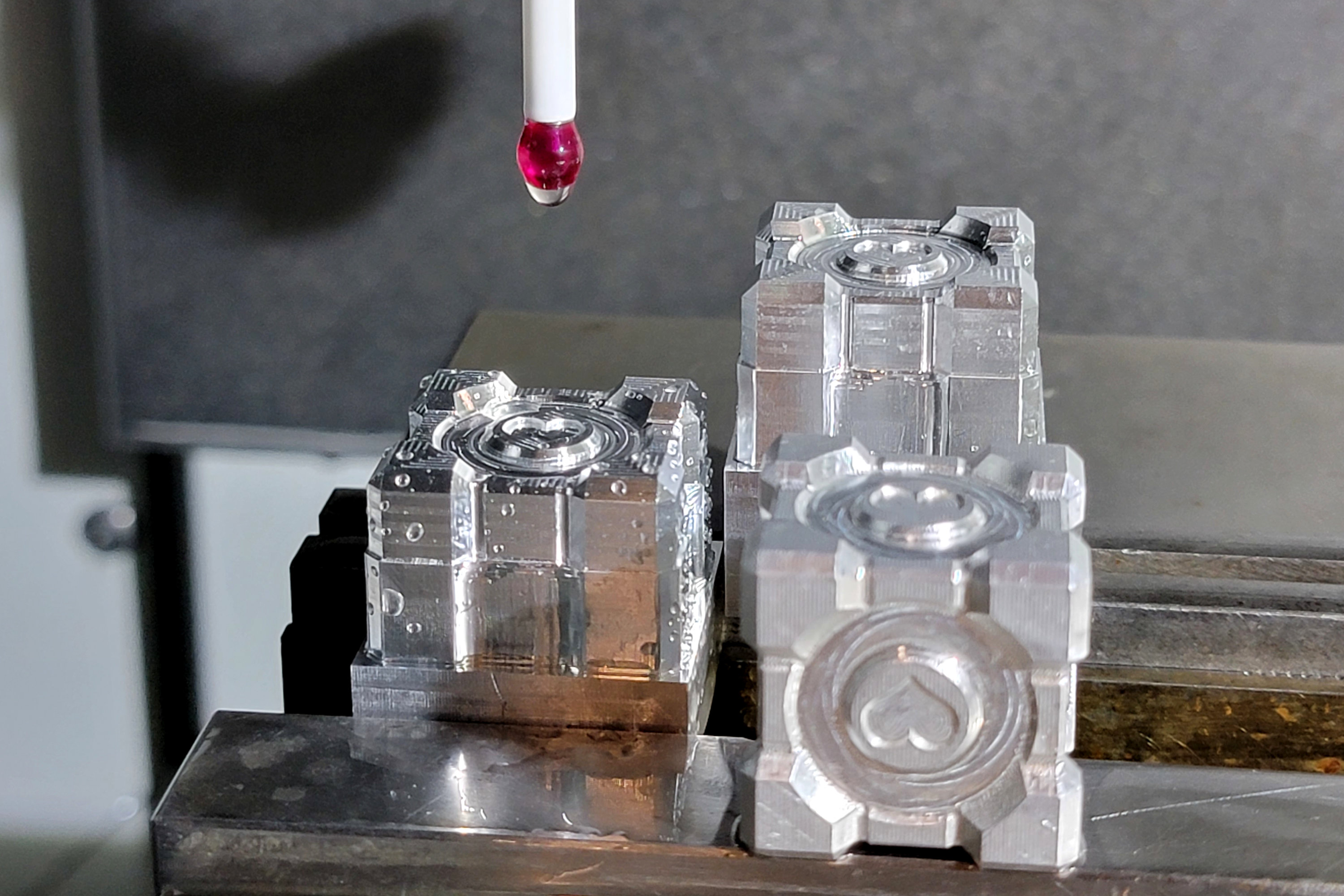

I wanted a metal companion cube. Therefore, I made a metal companion cube. It is exactly 1"3. This was my first solo project on a CNC mill, and the results are really cute.

Sandblasted matte finish

The machining was done on a HAAS CNC mill out of 6061 aluminum. Even at 15 000 RPM it took over

90 minutes to machine all 6 sides! It uses tiny tools, with the biggest being a 1/4" end mill, and going

all the way down to 1/16" end mill. Let's also not forget the 3D contouring toolpaths that were used to

make the non-standard side angles.

After roughing

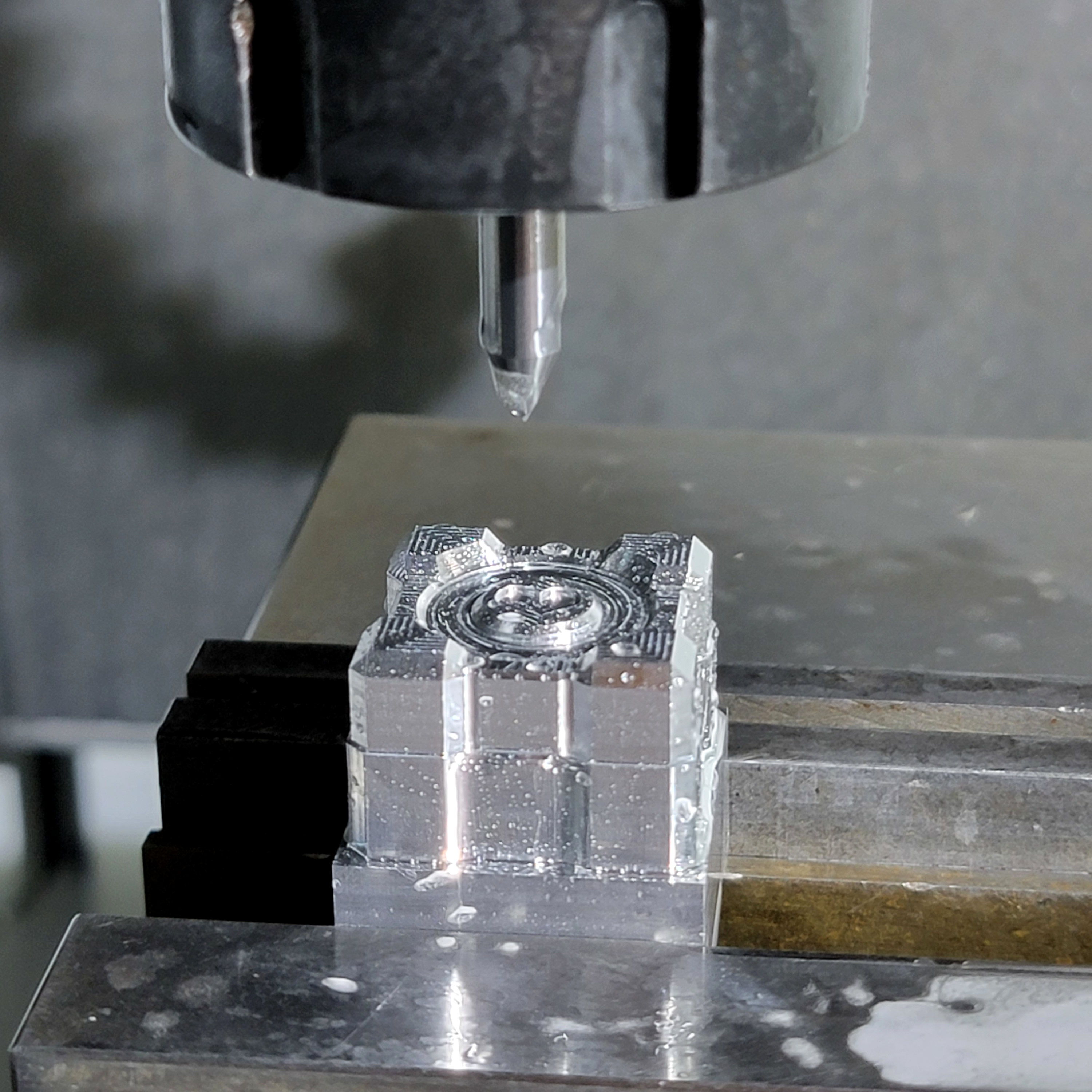

Almost done with the machining process

To speed up the machining process, after the first two faces, it is the same code run four times to finish the remaining faces. There is very little material to remove, but setting the stock work offsets was getting really tedious. This gave me an idea: surely the automated probing macros must be scriptable! And they in fact are, just like any other G-code commands. wrote a G-code script that find the cube, as long as I put it within 2" of it's last position inside the vise. After the cycle finished, I could just flip the cube 90°, press the big green start button, and walk away for 15 minutes. Not only did it feel unmeasurably satisfying to watch the machine work at 100% rapids, but it also saved me a lot of sitting around and not doing anything. I have since automated more complex manufacturing processes, but this will forever be my favorite.

I made a couple of the cubes