My First Large Drone Project

Roadside trash on highway medians causes significant environmental and economic harm in the United States. While prevention and public awareness remain the best long-term solutions, current methods of cleaning up existing litter are ineffective, dangerous, and expensive. Although ground robots have been successful at collecting trash in other conditions, the inaccessible and uneven terrain of highway medians is better suited for an autonomous aerial system. The Terrawarden drone, a one-meter-wide quadrotor with a 3-DOF manipulator and compliant gripper, addresses the problem of roadside litter by autonomously detecting and retrieving trash using on-board perception. To validate the feasibility of this approach, a controlled experiment was designed in which the drone was tasked with detecting a beverage container, navigating to it, collecting it without landing, and then transporting it to a designated collection point. The drone successfully completed each of these tasks, demonstrating the working principle of the proposed system and its potential for future research and deployment.

The Results?

A working proof of concept, professional-looking product video, American-style poster, and a long report.

Final project video

Presentation poster

If you would like to read the full report, click here

The Build

It all began with an idea to combine sustainability and robotics. After concluding that a swarm of a land robot and an aerial eye would be too complex for a team of six undergraduates, we settled on a single aerial robot with a manipulator. I took the lead in the project management, mechanical design, flight stack and embedded code, and then helped wherever I could.

This is me in the early stage of the project. Completely rebuilding the drone frame to fit everything we needed.

Of course, we had to have some fun while working on the project.

The first flyable iteration, with the arm v1 and gripper v1 installed.

A closeup detail at the compliant gripper v2 holding a Dr Pepper can.

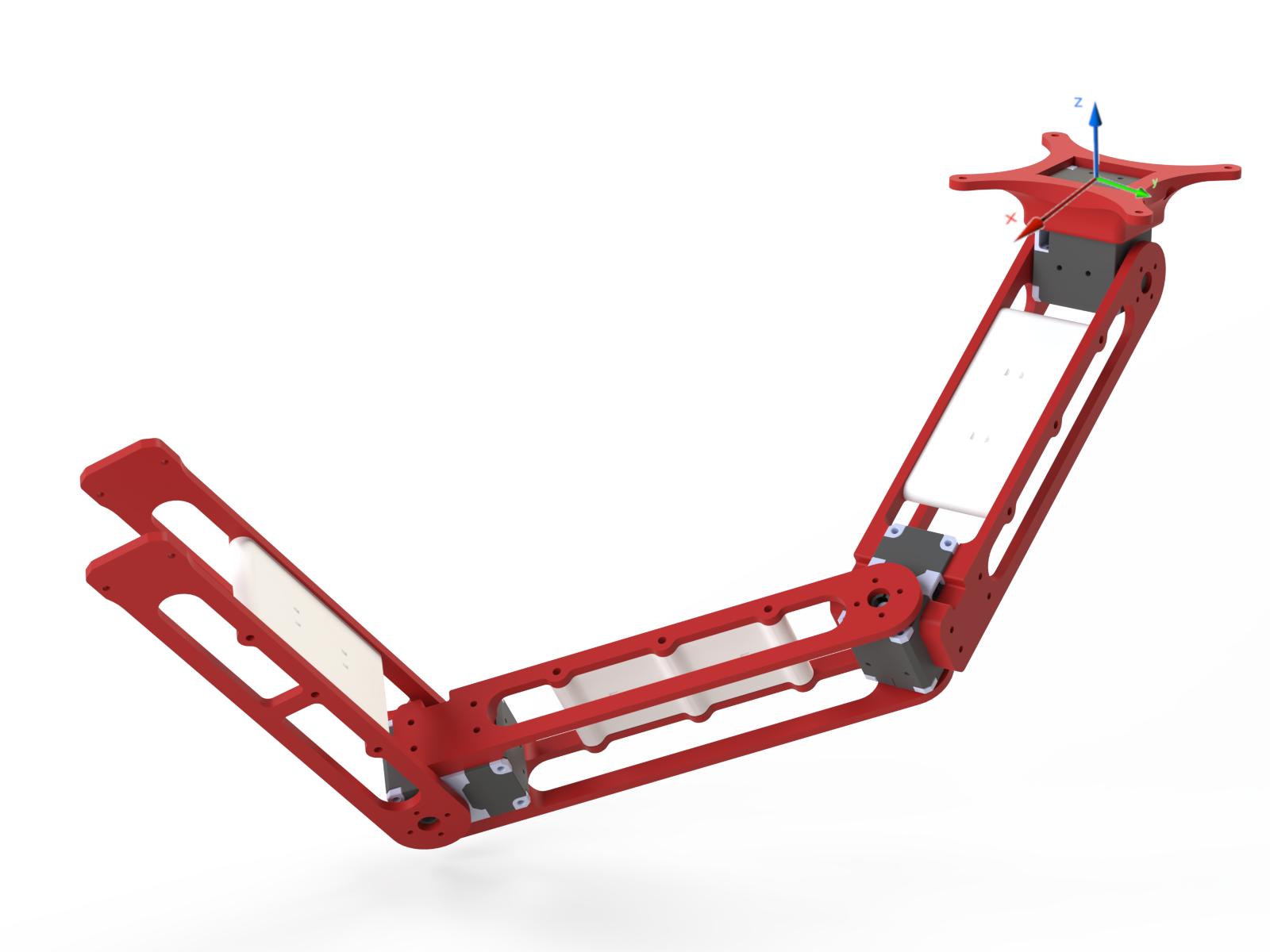

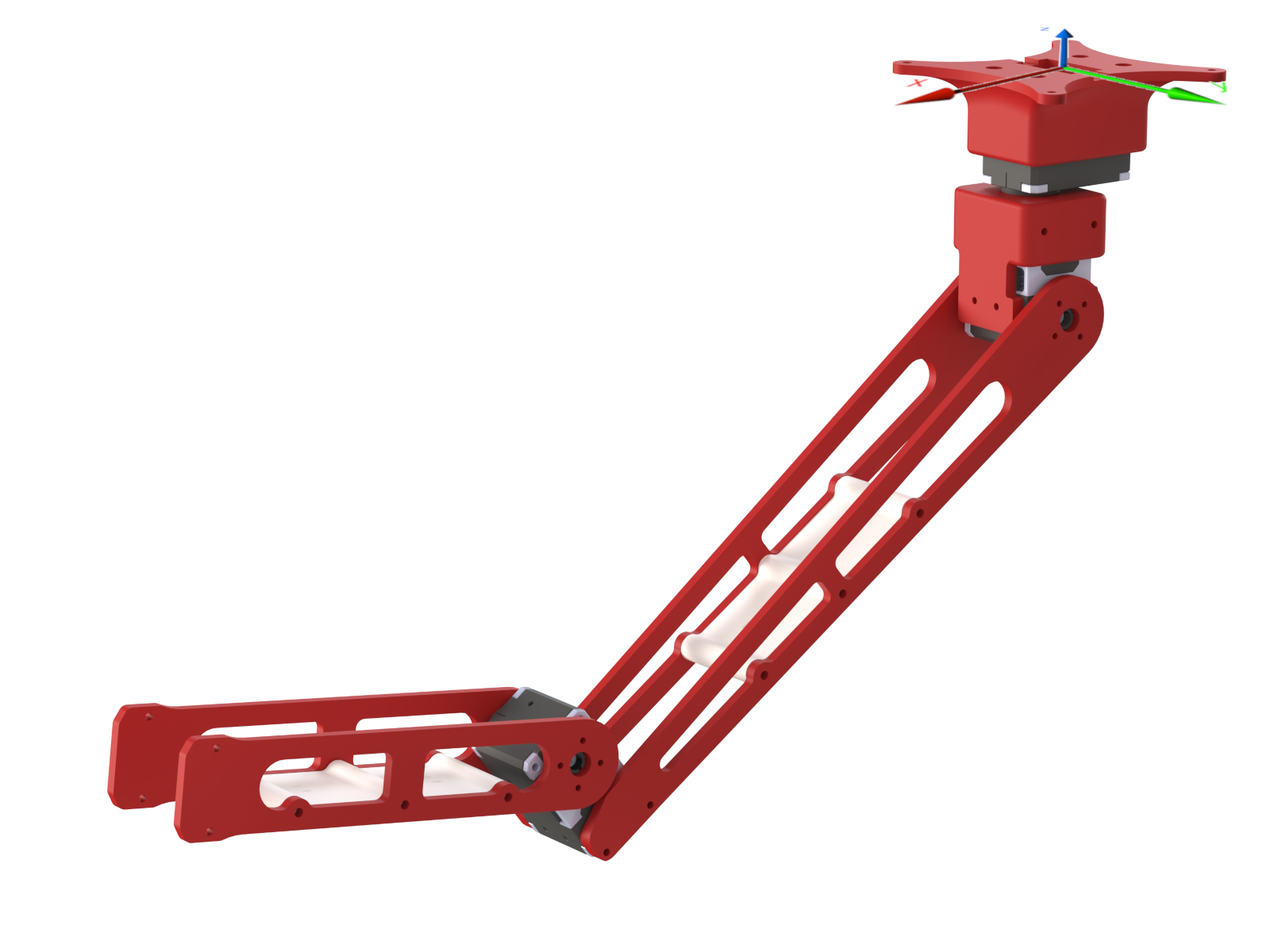

One subassembly was the lightweight arm and gripper, which we designed and 3D printed in-house (out of glass fiber-reinforced ABS). The arm was actuated by three servos, allowing for a wide range of motion to pick up trash from various angles. Initially, we wanted to wrap around the drone's legs to pick up objects, but this construction proved too front-heavy. Instead, we opted for a more traditional arm configuration, which provided better balance and stability. The gripper was designed to be compliant, allowing it to conform to the shape of the trash being picked up, ensuring a secure grip.

This is the first arm configuration, to allow for a wider range of motion in the front.

Eventually, due to being too front-heavy, we switched to a more traditional arm configuration.

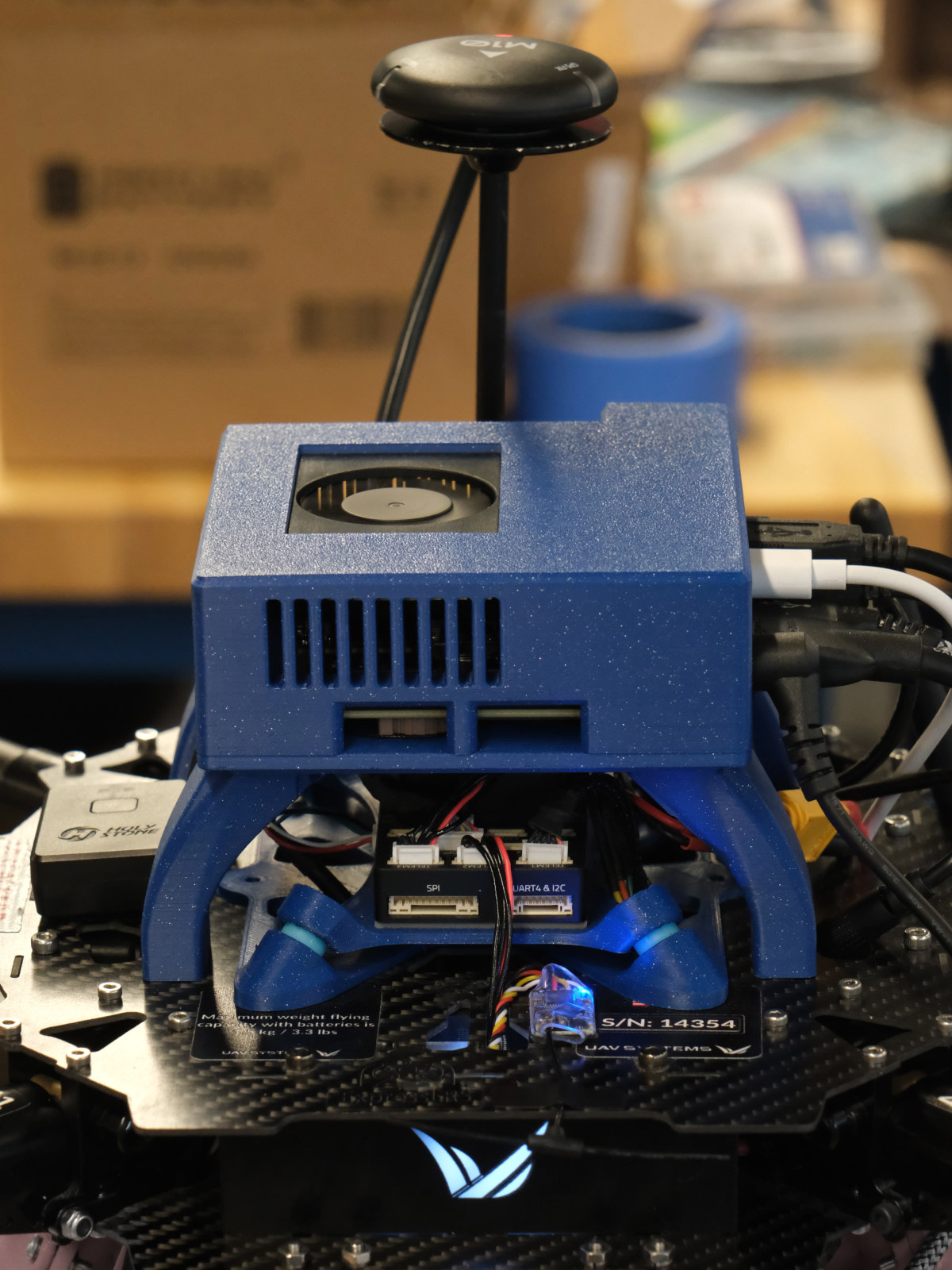

The brains of the operation was a Pixhawk 6X flight controller, running PX4 firmware tightly coupled with a Jetson Orin NX computer crunching stereo-vision data from an Intel RealSense D455 camera. The Pixhawk handled the low-level flight control, while the Jetson ran a ROS2 node for computer vision and high-level decision-making. The two communicated over uXRCE-DDS Ethernet client, allowing for seamless integration of perception and control. The entire system was powered by a massive 6S 5000mAh LiPo battery, giving us about 15 minutes of flight time while carrying the additional weight of the arm and gripper.

This is the flight stack that I worked on. It includes a Pixhawk 6X, Jetson Orin NX, and an ELRS receiver.

Hovering with the arm v2 and gripper v2 stowed and locked above the leg.

Drone in hover inside our indoor test arena, in the pre-grasp position with the arm v2 and gripper v2 deployed.

I also served as the project’s pilot and flight-safety officer, planning and supervising all test flights to ensure both people and hardware survived our experiments. From pre-flight checklists to emergency procedures, I handled the balance between pushing the limits and keeping the drone – and the team – in one piece.

One of the many long debugging sessions, moving one step closer at a time.

A still taken from one of the autonomous test flight videos.

- Key metrics achieved:

- Autonomous flight and trash pickup

- Position hold within ±10 cm of setpoint

- Manipulator precision within ±2 cm

- Gripper lifts payloads up to 350 g

- Trash detection precision 83.2 % / recall 60.9 %

- Detection range up to 4 m

This worked well – right up until the final week, when I swapped the pilot seat for the camera. Drawing on my hobby in filmmaking, I was busy shooting the project video while someone else took over flying duties. What could possibly go wrong?

The Hard Parts (of a Student Team)

In the end, our drone successfully took off, identified a can, navigated toward it, and grasped it using the 3-DOF manipulator. During testing, we found a delicate balance: lightweight cans were blown away by rotor wash, while heavier ones exceeded the arm’s lifting capacity. With limited time, we did not fully solve this challenge, but the system continued under a PhD student in our advisor's lab, so we may see a better second version.

As with any complex team project, there will be members who do not give it all, members who underperform and report inflated progress, and members who write code through quick-and-dirty methods instead of using proper standards that bite back later. This then causes strain on the team and delays in the project, and more stress for me, a responsible project manager. Moreover, a week before the final deadline, the drone crashed and burned out a motor. After assessing priorities, we decided to focus on completing the remaining materials – the video, poster, and the written report – while replacement motors were ordered. This decision proved wise in hindsight, as the remaining deliverables required all of our remaining time, and we worked until the last minute to finish the final report. Before handing over the project, I ensured the drone was flight-ready, with all components tested and functional. As a team we really pushed on getting the full pipeline to work until the last possible minute.